The thermal conductivity of tungsten electrode has an important impact on the welding process of argon arc welding, which is manifested as follows:

Firstly, tungsten has high thermal conductivity, which helps to quickly conduct heat generated at the electrode end to the electrode rod body and avoid local overheating. Good thermal conductivity can reduce the temperature peak at the electrode tip, reduce ablation and melting loss, and extend the service life of the electrode.

Secondly, thermal conductivity affects the temperature distribution of the electrodes, which in turn affects the stability and concentration of the arc. When the heat is evenly distributed, the arc is more stable, the welding heat input is more controllable, and the weld quality is better.

In addition, thermal conductivity is also related to the heat dissipation efficiency during the welding process, especially during high current or long-term welding, good thermal conductivity can effectively prevent performance degradation caused by electrode overheating.

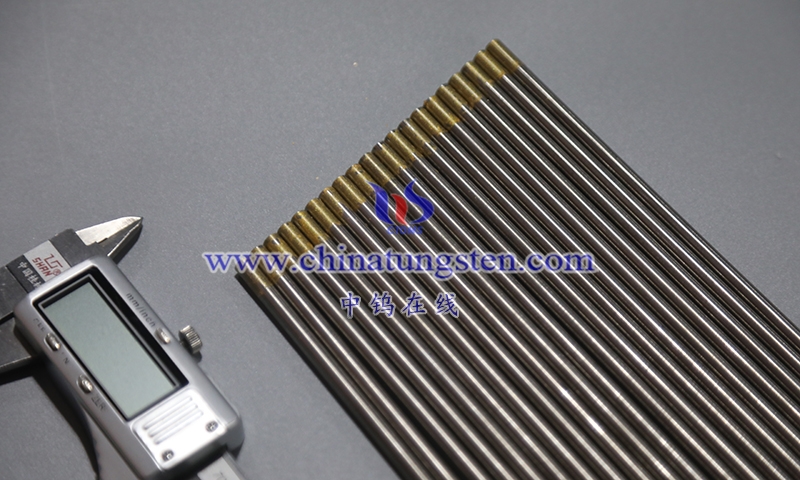

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595