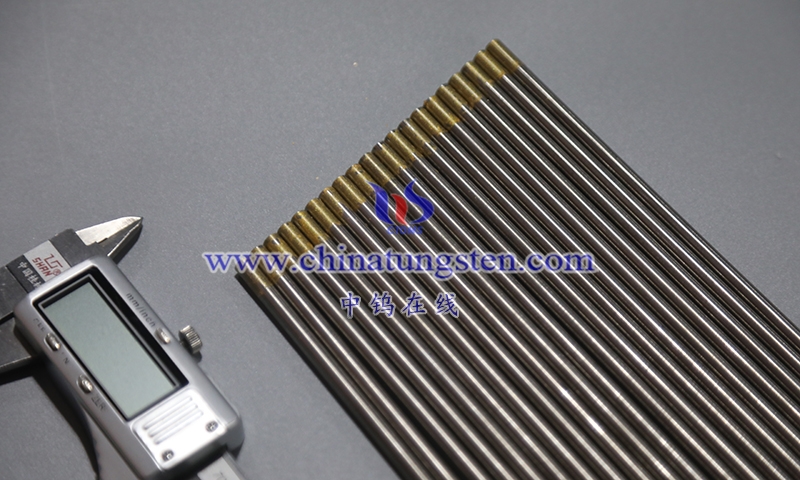

Tungsten electrodes have good corrosion resistance, but their specific performance is affected by a variety of factors:

The Material Itself Is Stable

Tungsten metal has strong corrosion resistance to most acids, alkalis, and oxidizing agents at room temperature, and can resist oxidation and chemical corrosion, which ensures that the tungsten electrode will not be easily damaged by corrosion during the welding process.

High Temperature Oxidation

Although tungsten has a high melting point and is resistant to high temperatures, when exposed to high temperatures in the air, the surface of tungsten will gradually oxidize to form tungsten oxide (WO3), which will affect the electrode performance to a certain extent. Protective gas environments (such as argon) can effectively reduce the risk of oxidation.

Welding Environmental Impact

The quality and flow rate of the shielding gas during the welding process play a key role in the corrosion resistance of tungsten electrodes. Insufficient gas purity or unstable flow rate can expose the electrode head to corrosive gases such as oxygen and moisture, leading to increased ablation and corrosion.

Surface Treatment

Modern tungsten electrodes are usually alloyed (such as adding thorium, lanthanum, cerium and other elements) and surface treatment to improve their corrosion resistance and ablation resistance, and extend their service life.

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595