Metallographic analysis of tungsten electrodes is an important method to evaluate their internal structure and quality, and the main steps are as follows:

Sampling Preparation

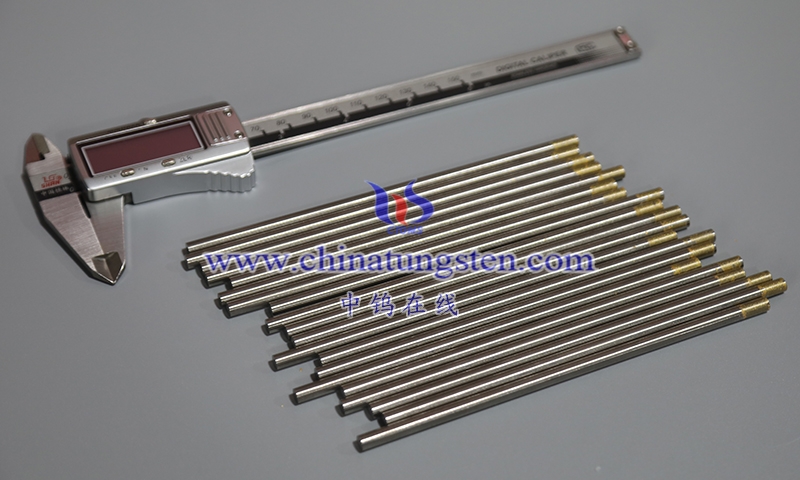

Cutting the appropriate size of the specimen from the tungsten electrode material usually requires representativeness to avoid surface contamination or damage.

Sample Mosaic

Specimens are cold or hot-mounted to facilitate subsequent polishing and keep the sample intact.

Grinding And Polishing

Grind the surface of the specimen with sandpaper of different particle sizes in turn until the surface is flat and free of scratches, and then use polishing agent to mirror polish to ensure clear observation under the metallographic microscope.

Corrosion Treatment (if Required)

Depending on the material type of the tungsten electrode, the sample is corroded with a suitable chemical corrosion solution to reveal grain boundaries and microstructure characteristics.

Microscopic Observation

Use optical microscopy or scanning electron microscopy (SEM) to observe the grain size, morphology, defects (e.g., inclusions, cracks, etc.) of the sample, and record tissue characteristics.

Image Analysis

Grain size is measured by image processing software, grain uniformity and tissue density are evaluated, impurity distribution is analyzed, etc.

Data Collation And Evaluation

Combined with the comparative analysis results of the standard specifications, it is judged whether the quality of the tungsten electrode material meets the requirements of use.

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595