The surface roughness of tungsten electrode does affect the welding quality, which is manifested as follows:

Arc Stability

Tungsten electrodes with smoother surfaces are more likely to form stable and concentrated arcs. Rough surfaces can lead to difficulty arc initiation or arc runout, affecting the continuity and uniformity of the weld.

Arc Performance

Electrodes with large surface roughness may increase the arc starting voltage due to small bulges or more impurities, making the arc starting unstable or delayed, and reducing the welding efficiency.

Electrode Consumption

Rough electrode surfaces are prone to the accumulation of oxides and impurities, increasing local hot spots, accelerating ablation and wear of electrode parts, and shortening electrode life.

Weld Quality

Unstable arcs and uneven heat input can lead to weld defects such as porosity, cracks, or uneven weld shapes, affecting weld strength and appearance.

Operational Safety

Rough electrodes can cause irregular arc runout, increasing operational risks, especially in high-precision welding.

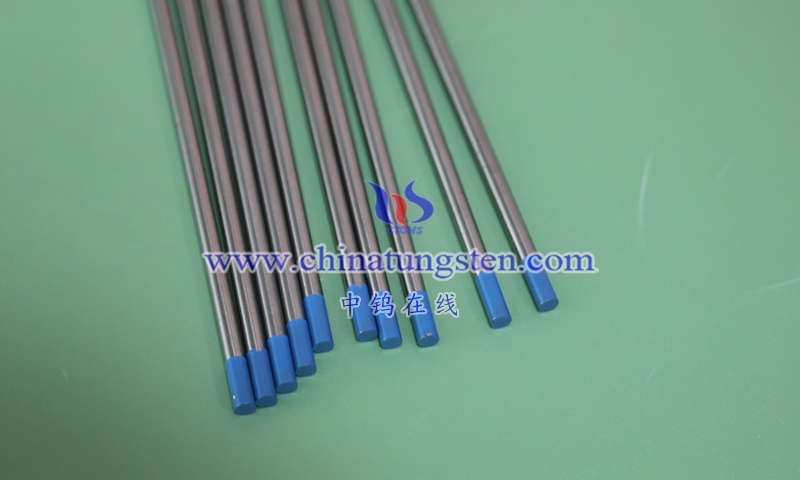

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595