The tip angle of the tungsten electrode has a direct impact on the arc shape, and the specific relationship is as follows:

1.Sharp Angle (small Angle, Such As Around 15°)

The arc is more concentrated and elongated.

Suitable for thin plate welding or where fine control of heat input is required.

The arc energy is concentrated, the heat-affected zone is smaller, and the weld is formed narrower and deeper.

2.Blunt Angle (large Angle, Such As 60° Or Even 90°)

The arc shape is wide and dispersed.

Suitable for thick plates or high-current welding, the arc is more stable and durable.

The heat input is more uniformly distributed, but the heat-affected zone is larger, and the weld width increases.

3.Intermediate Angle (such As 30°~45°)

Balanced with concentration and dispersion, suitable for a variety of welding needs, balancing arc stability and heat input control.

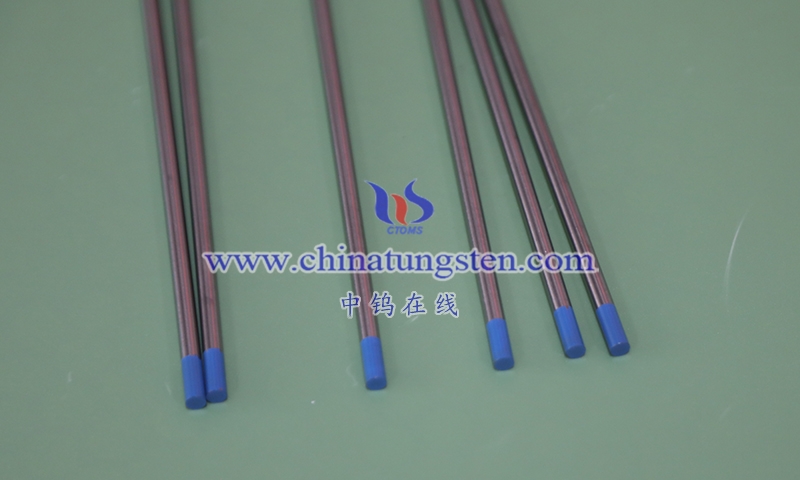

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595