The main detection methods for tungsten inclusions in welds are as follows:

Visual Inspection

Tungsten inclusions usually appear as black or dark small particles when viewed through a magnifying glass or microscope, especially in the weld root or weld section.

Metallographic Microscope Observation

The cross-sectional sample of the weld seam was taken and the morphology, distribution and size of the tungsten inclusions were observed under an optical microscope to judge the properties of the inclusions.

Scanning Electron Microscopy (sem)

The high-resolution observation of the weld section by SEM can clearly identify the tungsten inclusions and their binding to the matrix.

Energy Spectroscopy (eds)

In combination with SEM, energy spectroscopy was used to determine the elemental composition of the inclusions and confirm whether they were tungsten inclusions.

Ultrasonic Testing

The internal defects of the weld are detected by ultrasonic flaw detector, and tungsten inclusions may produce abnormal echoes due to different densities, which assists in judging the existence of inclusions.

X-ray Inspection

X-ray fluoroscopy can detect large inclusions inside the weld, but has limited sensitivity to tiny tungsten inclusions and is often used in conjunction with other methods.

Fracture Analysis

Microscopic analysis of weld fractures was carried out to observe the influence of inclusions on the fracture properties of welds, and tungsten inclusions were indirectly detected.

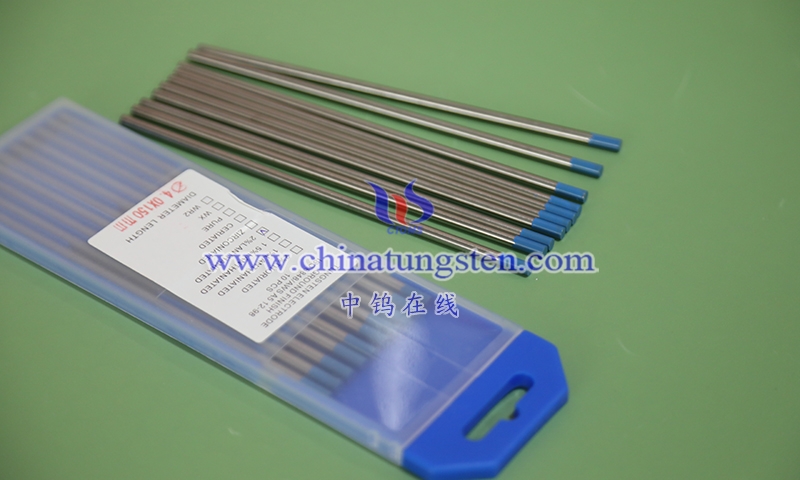

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595