There are indeed certain differences in the performance of tungsten electrodes produced by the same manufacturer, mainly due to the following aspects:

Raw Material Quality

The purity, impurity content, and alloy composition of tungsten powder used by different manufacturers may vary, which directly affects the melting point, wear resistance, conductivity, and arcing properties of the electrode.

Manufacturing Process

Powder metallurgy technology, sintering temperature, pressure control, and post-heat treatment processes during the manufacturing process can affect the electrode’s tissue structure and internal defects, thereby affecting its performance stability and service life.

Alloy Ratio

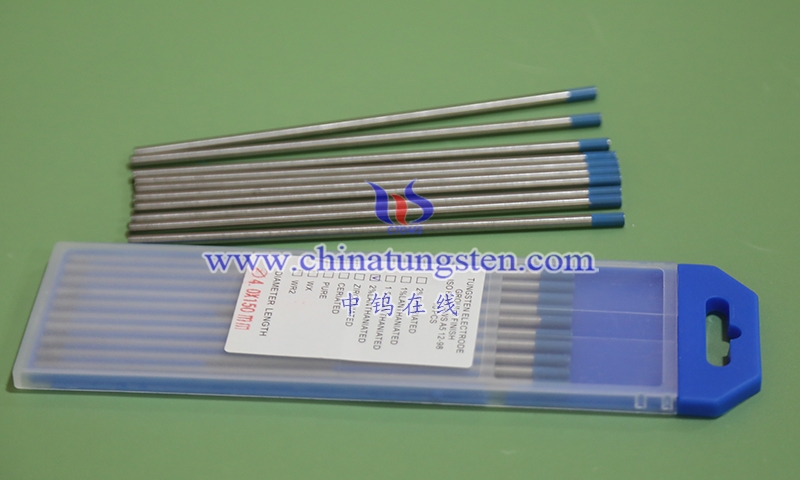

Some manufacturers add rare earth elements (such as thorium, cerium, lanthanum, zirconium) to tungsten electrodes in different proportions and purities, resulting in significant differences in arc voltage, ablation rate and arc stability of the electrodes.

Surface Treatment and Sharpening Quality

The processing accuracy, surface finish and tipping angle of the electrode head have a great impact on the arc initiation performance and arc concentration, and different manufacturers have different processing equipment and quality control levels, resulting in different user experiences.

Quality Control Standards

Manufacturers have different quality inspection standards and testing methods for products, which will affect the qualification rate and consistency of the final product.

Price And Positioning

High-end tungsten electrode manufacturers usually use more advanced technology and high-quality raw materials, with stable performance and long life; Low-priced products may have problems with fluctuating performance and reduced service life.

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595