Tungsten electrode cracking is a common problem in applications such as argon arc welding and plasma welding, especially in environments with high temperatures, high heat loads, or poor protection. To extend electrode life and ensure weld quality, the following precautions can be taken:

- Control Thermal Stress

Warm up slowly before welding to avoid sudden cooling and heating of the electrode;

After extinguishing the arc, let the electrode cool naturally, and do not blow cold air or water cool immediately;

Avoid frequent arcing and arc shutdown, reducing the number of thermal cycles.

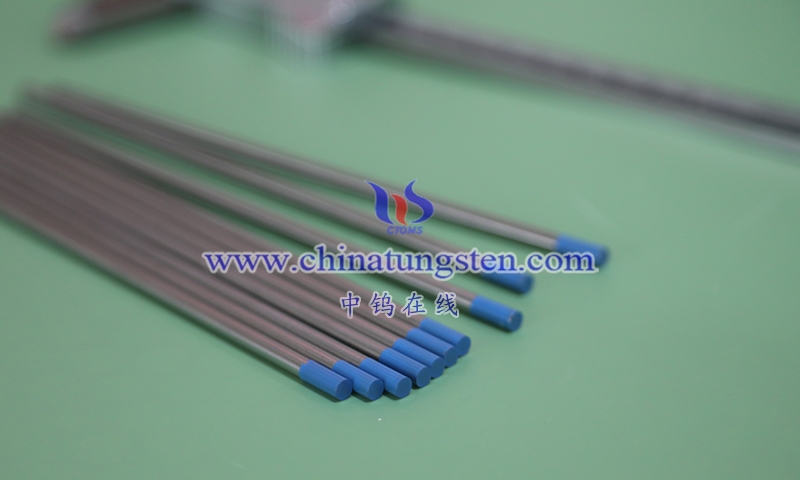

- Use High-quality Electrodes

Select high-quality tungsten electrodes with fine grains and uniform structure;

Avoid using electrodes with cracks, inclusions, or deformations on the surface;

Choose the appropriate model (such as WT, WL, WC, etc.) according to the welding method.

- Ensure Good Gas Protection

Use high-purity argon or helium to avoid mixing with impurities such as oxygen, water vapor, and hydrogen;

Adjust the appropriate gas flow rate to ensure that the arc zone is completely encapsulated;

Check that the nozzle is clogged and that the airflow is even.

- Set Welding Parameters Reasonably

Control the current within the allowable range of the electrode to avoid excessive current ablation of the tip;

Keep the arc stable to avoid sharp fluctuations in arc pressure;

Reduces direct contact between the electrode and the workpiece and prevents sticking.

- Grind The Electrode Correctly

Use a special grinding machine to grind along the axial direction to avoid lateral scratches;

Keep the electrode angle symmetrical and the surface smooth;

Regularly regrind the electrode to remove ablative or deformed parts.

- Pay Attention To Clamping And Operation Methods

The electrode should be clamped appropriately and should not be too TIGht or shaken.

Avoid mechanical impact or bending of the electrode during operation;

Store properly after welding to prevent bumps.

More details of tungsten electrodes, please visit website: http://tungsten.com.cn/tungsten-electrodes.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595