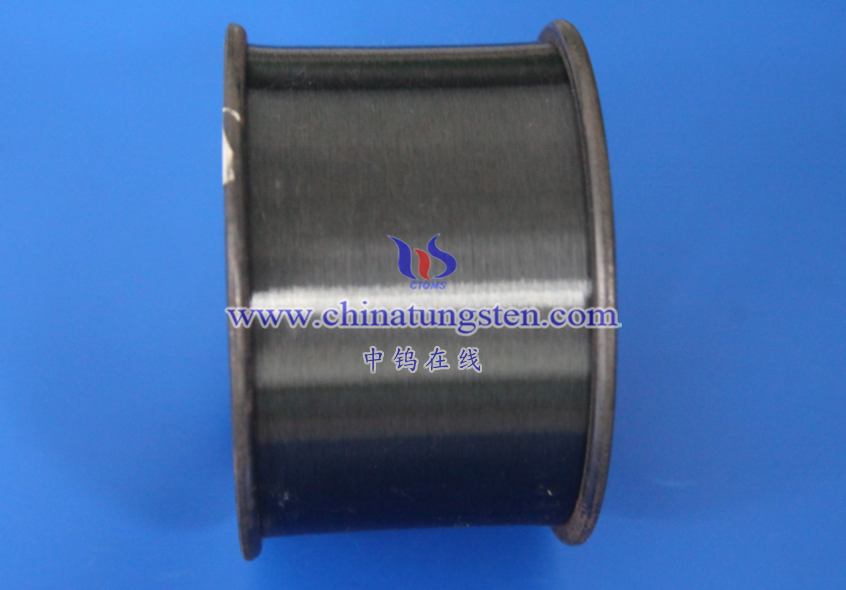

The microstructure of black tungsten wire is characterized by elongated, fibrous grain structures based on a body-centered cubic (BCC) crystal arrangement, with grains aligned along the wire-drawing direction. The surface exhibits rough microtopography with wire-drawing marks and residual graphite milk, while internal defects are minimal. Doping elements optimize the grain structure, enhancing high-temperature performance. These characteristics endow black tungsten wire with high strength and thermal stability at the microscopic level.

Grain Structure:

- Black tungsten wire features elongated grain structures, a result of the wire-drawing process. This process aligns tungsten grains along the drawing direction, forming a fibrous microstructure.

- Grain sizes are typically small (on the micrometer scale), with specific sizes depending on drawing process parameters and doping elements (e.g., potassium, aluminum, silicon). Doping elements (e.g., potassium) promote grain refinement or form specific grain boundaries, enhancing high-temperature creep resistance.

- The BCC crystal structure manifests as a regular atomic arrangement at the microscopic level, with clear grain boundaries.

Surface Microtopography:

- At the microscopic scale, the surface of black tungsten wire is relatively rough, displaying irregular textures or microscale roughness. This is due to residual lubricant (e.g., graphite milk) from the wire-drawing process and minor scratches caused by drawing dies.

- The surface may have trace carbon-based deposits (from graphite milk) adhering as thin layers or particles, affecting surface smoothness.

- Compared to polished cleaned tungsten wire, black tungsten wire lacks luster and has a more complex microtopography.

Internal Defects:

- The interior of black tungsten wire may contain minimal defects such as microcracks, voids, or inclusions, but high-purity tungsten (>99.95%) and stringent production processes keep these defects to a minimum.

- Doping elements may form tiny precipitates (e.g., potassium oxide particles) at grain boundaries, which help stabilize the crystal structure and reduce high-temperature deformation.

Fibrous Structure:

- During the wire-drawing process, tungsten’s microstructure is stretched into a fibrous organization, enhancing the wire’s mechanical strength and toughness, especially at high temperatures.

- The fibrous structure is aligned with the drawing direction, resulting in high tensile strength along the wire’s length.

Microscopic Observation:

- Under a scanning electron microscope (SEM), the surface of black tungsten wire reveals wire-drawing marks and slight irregular textures, with grain boundaries potentially visible.

- Transmission electron microscopy (TEM) can further reveal the atomic-level arrangement of the BCC crystal structure and the distribution of doping elements at grain boundaries or within grains.

More details of tungsten wire, please visit website: http://www.tungsten-wire.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten wire:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595