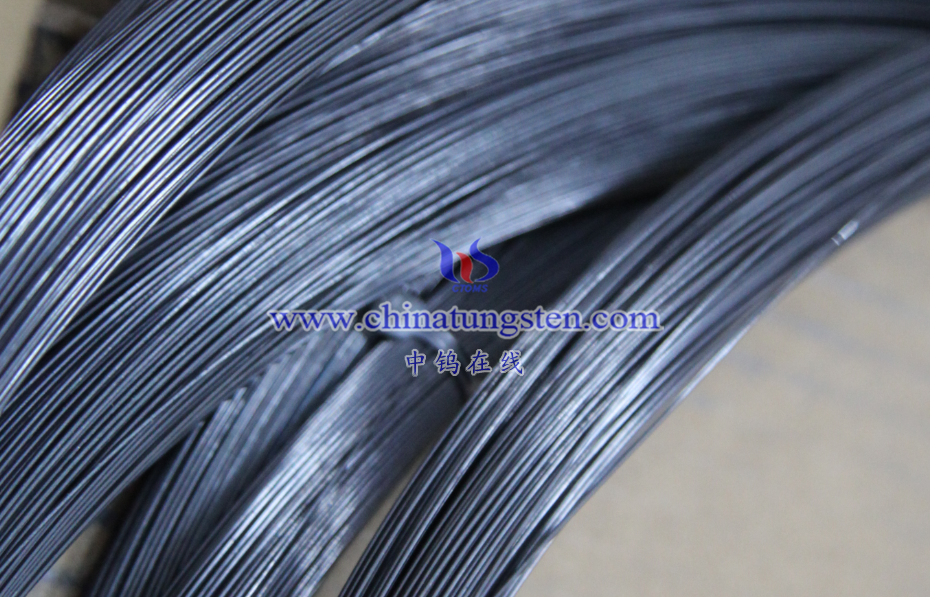

The ductility of black tungsten wire is relatively low among metal materials, but it can be moderately improved through doping, annealing, and other processes.

- Inherent Properties of Tungsten

- High Melting Point and Hardness: Tungsten has a melting point of 3422°C, the highest among all metals, and significant hardness (Mohs hardness 7.5-9.5). These properties make it challenging to achieve significant plastic deformation through conventional cold working (e.g., wire drawing or rolling).

- Brittleness Tendency: Pure tungsten is brittle at room temperature, exhibiting very poor ductility and a tendency to fracture. This is due to its body-centered cubic (BCC) crystal structure, which has limited slip systems at low temperatures, hindering plastic deformation through dislocation motion.

- Processing and Ductility Improvement of Black Tungsten Wire

- Doping and Alloying: To enhance ductility, tungsten wire is often doped with small amounts of elements such as potassium, aluminum, or silicon (e.g., tungsten-rhenium alloys). These elements form fine particles at high temperatures, inhibiting grain growth while promoting dislocation motion, thus improving room-temperature plasticity.

- Heat Treatment: Intermediate annealing (e.g., in a high-temperature hydrogen atmosphere) eliminates work hardening and restores the grain structure, further enhancing ductility. For instance, tungsten wire requires multiple annealing steps during drawing to prevent fracturing.

- Surface Modification: Black tungsten wire may undergo carburization or oxidation treatments, forming a surface layer of tungsten carbide or tungsten oxide. These coatings primarily improve wear resistance, corrosion resistance, or high-temperature stability but have limited impact on overall ductility, potentially even slightly reducing plasticity due to surface hardening.

- Ductility Performance in Practical Applications

- Limited Ductility: Even with optimized processing, the ductility of black tungsten wire remains significantly lower than that of common metals like copper or aluminum. Its elongation at break is typically between 1%-5% (compared to over 40% for copper), sufficient only for specific application requirements.

- Plasticity at High Temperatures: At elevated temperatures (above 1000°C), tungsten’s ductility improves significantly, allowing shaping through hot working (e.g., forging or extrusion). However, since black tungsten wire is typically used in applications requiring room-temperature stability (e.g., light bulb filaments or electron tube cathodes), high-temperature plasticity is not a primary consideration.

More details of tungsten wire, please visit website: http://www.tungsten-wire.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten wire:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595