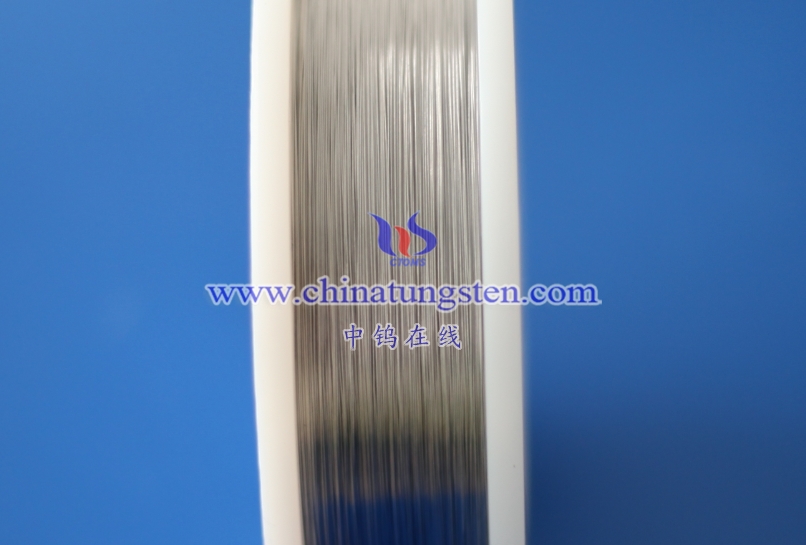

Cleaned tungsten wire is an ideal material for heating elements in high-temperature furnaces, particularly suited for vacuum furnaces or those protected by inert gases:

- Ultra-High Temperature Resistance: With a melting point of 3422°C, tungsten can operate stably above 2500°C, meeting the demands of high-temperature heat treatment, sintering, or smelting.

- Oxidation Resistance: In vacuum or inert gas environments (such as argon or nitrogen), cleaned tungsten wire resists oxidation, offering long service life and suitability for prolonged high-temperature operation.

- Efficient Heat Conduction: The low thermal expansion coefficient and excellent electrical conductivity of cleaned tungsten wire enable rapid heating and uniform temperature distribution, making it ideal for precision thermal processes such as semiconductor wafer annealing or ceramic sintering.

- Mechanical Stability: Cleaned tungsten wire resists deformation or fracture at high temperatures, accommodating complex heating element designs (such as spiral or mesh structures).

In oxidative atmospheres, cleaned tungsten wire or protective coatings must be used to prevent oxidation.

More details of tungsten wire, please visit website: http://www.tungsten-wire.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten wire:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595