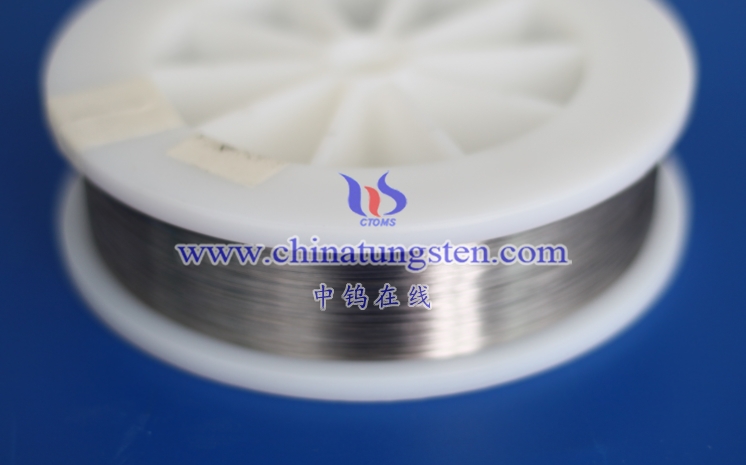

Halogen lamps use coiled tungsten filaments heated to ~2500–3100°C. Lifespan is limited by tungsten evaporation, causing thinning and breakage. The halogen cycle redeposits evaporated tungsten, extending life to ~2000–3000 hours. Cleaned tungsten wire is essential; electrolytic polishing removes surface roughness and contaminants via anodic dissolution.

Impact of Electrolytic Polishing on Lifespan

Electrolytic polishing extends filament life by creating a smooth, clean surface (Ra < 0.1–0.5 μm), reducing hotspots and notching. Benefits include:

- Uniform evaporation and redeposition via halogen cycle

- Lower impurity-induced sagging and vibration failure

- 10–30% longer life; less lumen loss over time

| Aspect | Unpolished Wire | Polished Wire |

|---|---|---|

| Roughness (Ra) | 0.5–2 μm | 0.05–0.5 μm |

| Evaporation | Uneven, notching | Uniform thinning |

| Lifespan Gain | Baseline | +10–30% |

Used in premium halogen lamps (e.g., automotive H4). Excessive polishing may reduce wire thickness slightly. Complements non-sag doping for optimal durability.

More details of tungsten wire, please visit website: http://www.tungsten-wire.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of tungsten wire:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595