Manufacturing process precision control serves as the decisive link translating theoretical design into actual shielding effectiveness for tungsten alloy shielding containers, encompassing the entire workflow from powder mixing, forming, sintering, mechanical machining, surface treatment, to final inspection.

Powder mixing uniformity determines microscopic distribution of tungsten particles and binder phase; any segregation may create localized low-density or weak-absorption zones. Pressure uniformity and green-body density consistency during forming directly influence whether closed pores or uneven shrinkage occur post-sintering. Sintering process control of temperature field, atmosphere purity, and holding time determines achievement of full densification and microstructural homogenization; minor fluctuations can lead to porosity or abnormal grain growth.

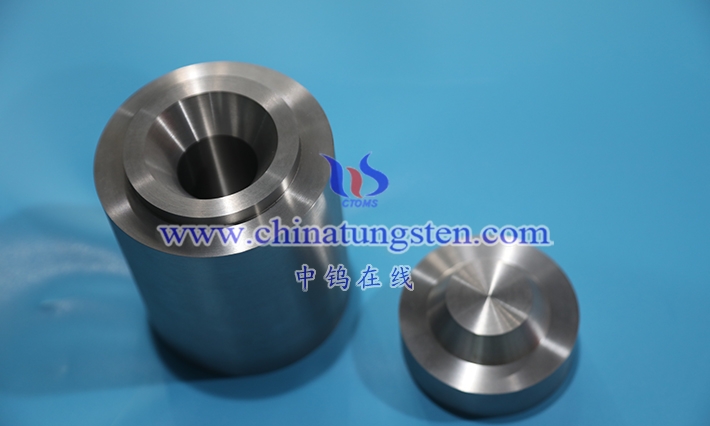

Mechanical machining precision governs realization of minimum wall thickness, labyrinth clearance, sealing surface flatness, and inner surface roughness; any out-of-tolerance condition may become a preferential leakage path or contamination trapping site. Surface treatment thickness uniformity and adhesion determine long-term retention of corrosion resistance and decontamination performance. Final inspection of dimensions, density, leakage, and hot calibration provides comprehensive verification of all process errors.

Manufacturing process precision control eliminates microscopic and macroscopic defects in material and structure, ensuring that the shielding effectiveness of tungsten alloy containers in nuclear medicine hot cells, isotope production, and industrial irradiation facilities remains highly consistent with design expectations.

More details of tungstate product, please visit website: http://www.tungsten-alloy.com/index.htm

Please contact CHINATUNGSTEN for inquiry and order of tungstate:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595