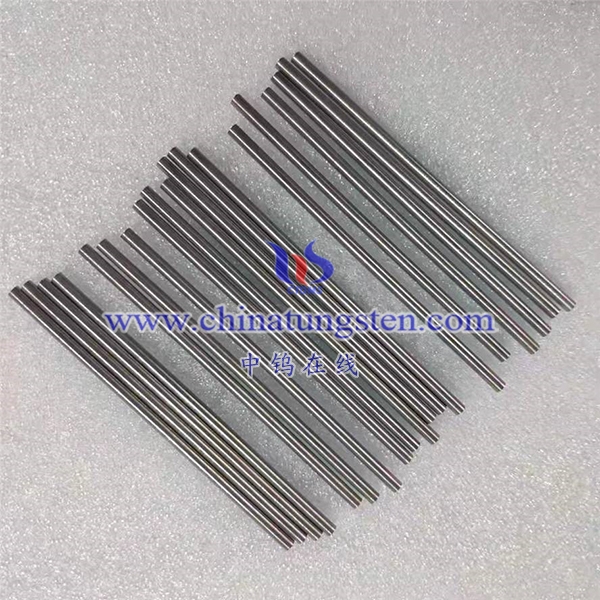

Tungsten needles are slender, sharp metal needles made from tungsten metal that are commonly used in industrial and laboratory applications. It has the characteristics of high melting point, high hardness, high thermal conductivity, etc., and can be used in high temperature, high pressure, and high wear-resistant environments.

The manufacturing process of tungsten needles includes material selection, heating treatment, drawing treatment, further processing, polishing treatment and quality inspection. The purity and composition of the tungsten needle have an important impact on its mechanical and electrical properties. During the manufacturing process, the control of parameters such as temperature and pressure is very important to ensure that the shape and size of the tungsten needle meets the requirements and to avoid cracks and other defects.

Tungsten needles are widely used in many fields, such as heating elements of high-temperature furnaces, filaments of electron tubes, electrodes of electric light sources, etc. The advantages of tungsten needle such as high melting point, high density and high thermal conductivity make it have excellent performance and stability in these fields. In addition, tungsten needles also have good corrosion resistance and high temperature resistance, and can be used for a long time in high temperature and corrosive environments.

In short, a metal tungsten needle is a slender metal needle made of metal material with excellent performance and high melting point, and has a wide range of applications.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595