The EDM electrode is a tool used in the Electrical Discharge Machining (EDM) process. Electrical discharge machining is a non-traditional metal processing method. Through the principle of electric spark discharge, high-energy electrons are discharged to the surface of the workpiece, thereby forming tiny discharge pits on the surface of the workpiece, and finally completing the processing of the workpiece. The EDM electrode plays the role of conduction and discharge in this process.

The following are some characteristics and functions of EDM electrodes:

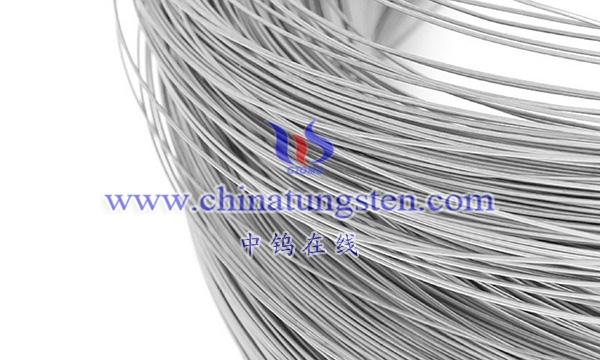

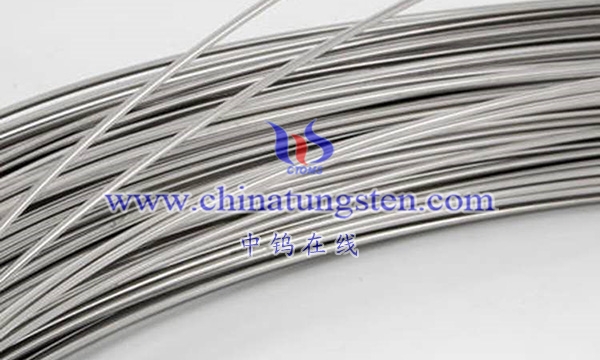

1. Materials: EDM electrodes are usually made of metals with high melting points, one of the most common materials being tungsten. Tungsten is an ideal electrode material for EDM due to its high melting point, high electrical conductivity and low EDM wear rate. Other materials, such as copper and copper alloys, can also be used in specific applications.

2. Electrical conductivity: The EDM electrode must have good electrical conductivity in order to transfer electrical energy to the workpiece surface during the discharge process. The conductivity of EDM electrodes directly affects the efficiency and accuracy of machining.

3. Wear resistance: Since EDM involves wear of the electrode surface during spark discharge, the electrode needs to have high wear resistance to extend its service life.

4. Stability: EDM electrodes need to maintain stability throughout the entire machining process to ensure accuracy and consistency.

The EDM electrode is a key component in the EDM process, and its design and material selection are crucial to the efficiency and processing quality of the entire machining process.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595