Customizing tungsten probes for wafer testing involves multiple steps that need to take into account specific test needs, application scenarios, and customer-specific requirements. Here is the customization process in general:

1. Understand customer needs

Before starting customization, manufacturers need to fully understand the customer’s specific needs. This may include:

• Testing Requirements: Type, size and performance of circuit components that the customer needs to test.

• Environmental conditions: Under what environmental conditions the customer plans to conduct testing, such as high temperature environment, high vacuum environment, etc.

• Special requirements: Are there any special test requirements, such as multi-channel design, special-shaped test points, etc.

• Production scale: The quantity required to be produced to determine whether large-scale production is required.

2. Select probe type

Select the appropriate probe type according to customer needs. For example:

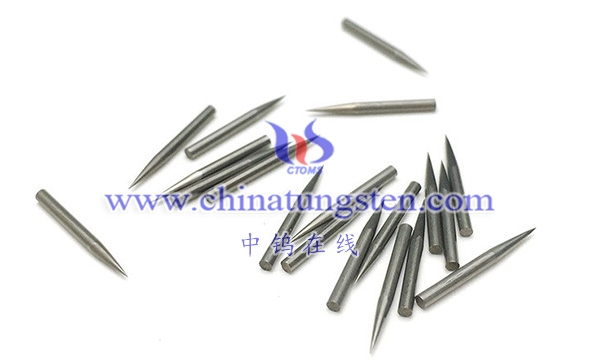

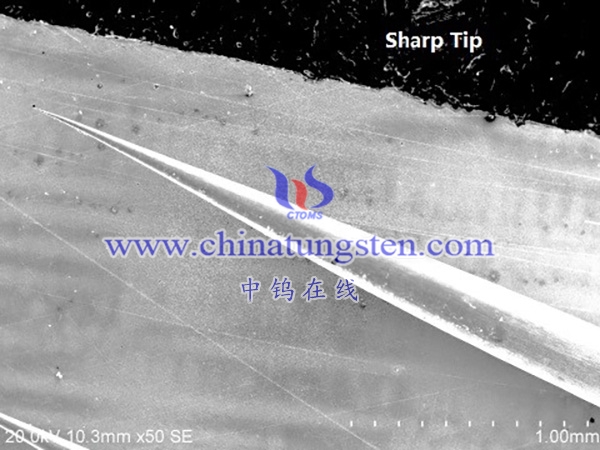

• Sharpened design: If high-precision testing is required, a probe with a sharpened tip design may be selected.

• Special shape design: If the test point has a special shape, a specially shaped probe may need to be designed.

• Multi-channel design: If you need to test multiple points simultaneously, choose a probe with a multi-channel design.

3. Material selection

Select the appropriate material. Typically the tip of a wafer test tungsten probe is made of tungsten or a tungsten alloy. The choice of material will affect the conductivity, wear resistance, high temperature stability and other properties of the probe.

4. Size and cutting-edge design

Design an appropriate tip based on the size and shape of the test point. This may include the determination of tip geometry, length, diameter, etc.

5. High temperature stability design

If the test will be performed in a high-temperature environment, ensure that the probe has sufficient high-temperature stability. This may require special designs and materials to prevent the probe from losing performance at high temperatures.

6. Customized services

Some manufacturers provide customized services and can make some special designs according to the specific needs of customers. This may include customer identification, special packaging requirements, etc.

7. Sample testing and verification

Before mass production, some samples are usually made for testing and verification. This helps ensure that the probe is designed to meet the customer’s needs, while also allowing for some performance testing and tuning.

8. Mass production manufacturing

Once the sample passes testing and verification, it can be manufactured into large-scale production. This may involve advanced manufacturing processes and equipment to ensure a high level of consistency from probe to probe.

9. After-sales service and technical support

Provide after-sales service and technical support to ensure that customers receive necessary support during use. This includes maintenance services, technical training, remote support, and more.

10. Quality Control

Establish a quality control system to ensure that each wafer test tungsten probe produced meets relevant standards and specifications. This is achieved through rigorous quality inspection, testing and certification.

11. Environmental and Sustainability Considerations

Consider environmental protection and sustainability during the manufacturing process, using sustainable materials and processes to reduce environmental impact.

12. Maintain communication with customers

Maintain close communication with customers to ensure that customer needs are understood throughout the entire customization process and possible problems that may arise are resolved in a timely manner. This communication can occur through regular progress reports, meetings, emails, etc.

13. Updates and improvements

As technology continues to evolve, manufacturers need to continually monitor industry trends and the emergence of new technologies. Products are regularly updated and improved to ensure they remain competitive and adaptable.

More details of tungsten needles, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595