The following factors need to be considered during the design and manufacturing process of high-density tungsten alloy drone counterweights:

- Performance requirements: When designing and manufacturing high-density tungsten alloy UAV counterweights, its performance requirements need to be considered, including density, strength, high temperature resistance, electromagnetic shielding performance, etc., to ensure that the quality and stability of the counterweights meet Require.

- Raw material selection: The selection of raw materials has an important impact on the performance and cost of high-density tungsten alloy. It is necessary to select tungsten powder, nickel powder, iron powder and other raw materials that meet the requirements, and ensure their quality and stability.

- Manufacturing process: The manufacturing process also has an important impact on the performance and cost of high-density tungsten alloy drone counterweights. It is necessary to select appropriate pressing molding, sintering, processing and other processes, and control various process parameters to ensure product quality and stability.

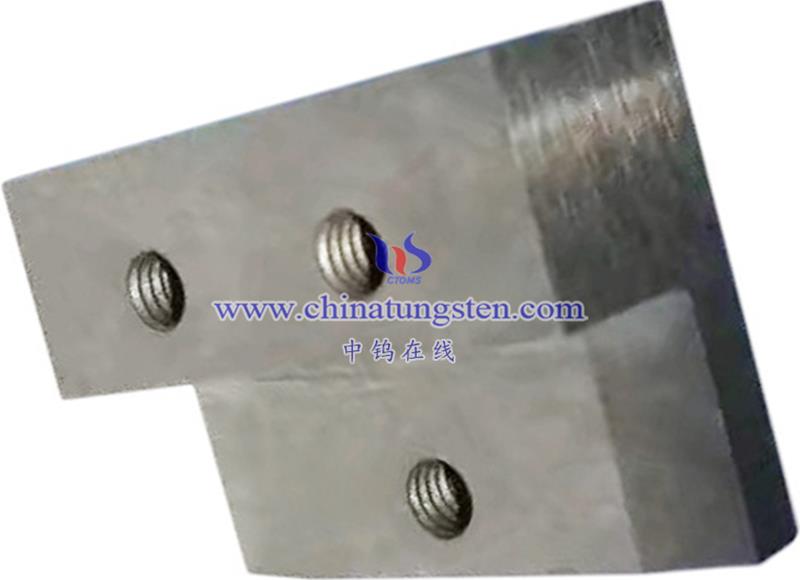

- Accuracy requirements: The accuracy of the drone’s counterweight has an important impact on its stability and performance. It is necessary to consider the shape, size and accuracy requirements of the weight block, and select appropriate processing and processing methods to ensure the accuracy and quality of the product.

- Environmental protection: High-density tungsten alloy is an environmentally friendly material. It is necessary to consider its environmental protection during the production and manufacturing process, and select raw materials and processes that meet environmental protection standards to reduce the impact on the environment.

- Cost factors: The cost of high-density tungsten alloy drone counterweights is relatively high, and its cost factors need to be considered. It is necessary to reduce costs and improve production efficiency as much as possible while ensuring product quality and stability.

In short, the design and manufacturing process of high-density tungsten alloy drone counterweights need to consider performance requirements, raw material selection, manufacturing processes, accuracy requirements, environmental protection and cost factors to ensure product quality and stability. And meet the needs of various application scenarios of drones.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595