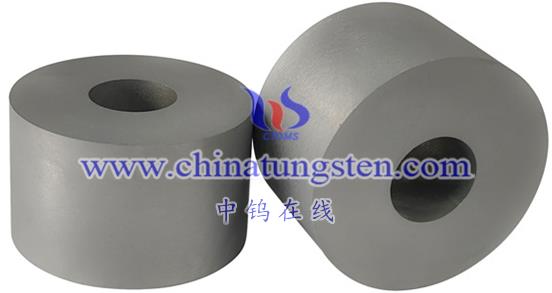

W-Ni-Fe series tungsten alloy is an alloy based on tungsten (about 90~98%) and added with nickel, iron, copper or other components. It is characterized by high sintering density, good strength and plasticity, and certain ferromagnetism. The specific gravity of this alloy is generally 17.0 to 18.5, which is 50% heavier than lead. It is a good electrical and thermal conductive material.

The advantages of tungsten-nickel iron alloy include:

- High density: The density of the alloy is usually between 16.5-18.75g/cm3, which is 50% higher than lead, which allows it to provide better weight performance in many applications.

- High strength and hardness: The tensile strength of tungsten-nickel-iron alloy is usually between 700-1000Mpa, which makes it an ideal choice for applications requiring high strength and durability.

- Good electrical and thermal conductivity: This alloy has good electrical and thermal conductivity, making it excellent in applications requiring these properties.

- Good weldability and processability: Tungsten nickel iron alloy is easy to weld and has good processability, which makes it highly flexible in the manufacturing process.

- Good ferromagnetism: Although not all tungsten-nickel-iron alloys are ferromagnetic, those that are can attract magnets, which can be useful in certain applications.

In addition, when the raw material ratio is different, the mechanical properties of different grades of W-Ni-Fe alloys are also different. Generally speaking, as the tungsten content increases, the density, hardness and tensile strength of W-Ni-Fe alloy become greater, while the elongation becomes smaller.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595