The ultrasonic testing method of high-density alloys has the following benefits for defect detection:

- Improve detection accuracy: Ultrasonic testing can detect small defects inside the material, such as tiny cracks, holes, etc., which helps to more accurately evaluate the internal quality of the material. Compared with other non-destructive testing methods, such as radiography, magnetic particle testing, etc., ultrasonic testing has higher sensitivity and resolution.

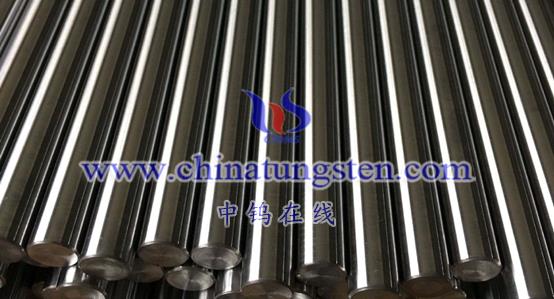

- Detect complex shapes and structures: Ultrasonic testing is suitable for materials of various shapes and structures, such as rods, plates, pipes, etc. By using different probes and setting parameters, the detection of materials of different shapes and sizes can be achieved.

- Real-time feedback: Ultrasonic testing can provide testing results in real time, which helps to promptly discover and solve problems during the production process, thereby reducing the scrap rate and production costs.

- No damage to materials: Ultrasonic testing is a non-destructive testing method and will not cause damage to materials. This helps protect the integrity and performance of the material during production.

- Applicable to various materials: Ultrasonic testing is applicable to various materials, including metals, non-metals, composite materials, etc. This makes it widely used in different material applications.

- Quantitative and qualitative analysis: Ultrasonic testing can provide quantitative and qualitative information about defects, such as defect size, location, shape, etc. This helps to better understand the performance and quality of the material.

- Improve production efficiency: Ultrasonic testing can be automated, thereby improving production efficiency. By integrating with other automation equipment, real-time detection on continuous production lines can be achieved.

In summary, the ultrasonic testing method of high-density alloys is of great help in defect detection. By improving detection accuracy, detecting complex shapes and structures, real-time feedback, no damage to materials, applicable to various materials, quantitative and qualitative analysis, and improving production efficiency, the quality and quality of high-density alloy products can be better guaranteed. safety.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595