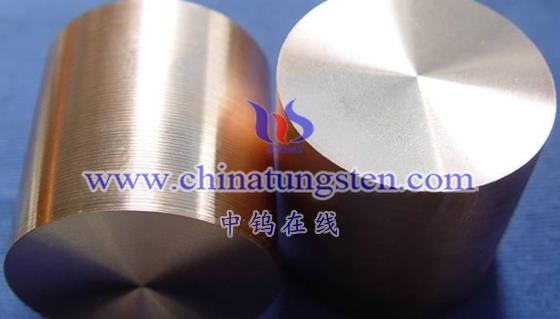

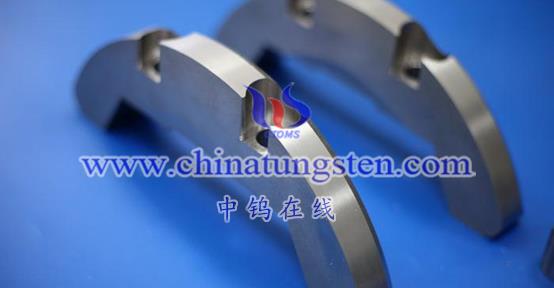

High-density tungsten alloy crankshaft counterweight is a crankshaft counterweight made of high-density tungsten alloy material. This kind of counterweight usually has the characteristics of high density, high strength, high hardness, excellent wear resistance and toughness, so it is widely used in automobile engines and other fields.

In the manufacturing process of high-density tungsten alloy crankshaft counterweights, methods such as powder metallurgy or liquid phase sintering are usually used to alloy tungsten with other metal or non-metal elements. These alloys have properties such as high density, high strength, high hardness, excellent wear resistance and toughness, allowing the manufacture of crankshaft weights with excellent performance.

The application fields of high-density tungsten alloy crankshaft counterweights are very wide, including but not limited to the following aspects:

- Automobile engine field: High-density tungsten alloy crankshaft counterweight can be used to manufacture crankshafts of automobile engines to improve the stability and reliability of the engine.

- Aerospace field: High-density tungsten alloy crankshaft counterweights can be used to manufacture crankshafts for turbine engines of high-speed aircraft to improve the stability and safety of the aircraft.

- Military field: High-density tungsten alloy crankshaft counterweights can be used to manufacture crankshafts for missile turbine engines to improve the stability and reliability of missiles.

In short, high-density tungsten alloy crankshaft counterweight is an engineering material of great value, widely used in many fields, and has broad application prospects.

The following is some specific data support:

- High density: The density of tungsten alloy is usually higher than that of pure tungsten because the addition of other metal or non-metal elements increases its density. The high density makes tungsten alloy have high strength and stiffness, and can withstand greater pressure and impact.

- Excellent mechanical properties: Tungsten alloy has mechanical properties such as high strength, high hardness, excellent wear resistance and toughness. These properties enable superior performance in environments withstanding high loads and impacts. Tungsten alloys are widely used in the manufacture of mechanical components that can withstand heavy loads and impacts, such as high-speed cutting tools, support structures for heavy machine tools, etc.

- Good oxidation resistance: Tungsten alloy is not easily oxidized in high temperature environments and maintains good stability. Compared with other metal materials, tungsten alloy has stronger oxidation resistance and can maintain the stability of its structure and performance in high temperature environments for a long time. This characteristic gives tungsten alloy advantages in applications in aerospace, military and other fields, and can meet reliability requirements in harsh environments.

- Excellent electromagnetic shielding performance: Tungsten alloy has good electromagnetic shielding performance and can effectively shield electromagnetic interference (EMI) and static electricity. This characteristic makes tungsten alloys of great significance in certain application fields that are sensitive to electromagnetic interference, such as medical treatment, aerospace, etc. By absorbing and reflecting electromagnetic waves, tungsten alloys protect surrounding electronic equipment and people.

- Non-toxic and environmentally friendly: The main components of tungsten alloy are tungsten and other non-toxic and environmentally friendly metal or non-metallic elements. Compared with other metal materials, tungsten alloy is harmless to the environment and human body, and is conducive to green production and sustainable development. During the manufacturing and use process, tungsten alloy does not produce harmful substances and meets modern environmental protection and health requirements.

- Good processing performance: Tungsten alloy has good processing performance and can be used for turning, milling, drilling and other processing operations, making it easy to manufacture parts of various shapes and sizes. This feature makes tungsten alloy less difficult and less expensive to manufacture, which is conducive to mass production. Good processing properties also enable tungsten alloys to meet the design requirements of various complex shapes and structures.

- Good corrosion resistance: Tungsten alloy has good corrosion resistance and can resist the erosion of various chemical substances. In a corrosive environment, a dense oxide film can be formed on the surface of tungsten alloy to prevent further corrosion. This characteristic makes tungsten alloy widely used in chemical industry, marine engineering and other fields.

- High thermal expansion coefficient: Compared with some metal materials, tungsten alloy has a higher thermal expansion coefficient. This means that the size of tungsten alloy changes greatly when the temperature changes. This feature needs to be considered during design to avoid stress concentrations and fatigue failures caused by thermal expansion. However, for some application fields that need to take advantage of its thermal expansion properties, such as precision instruments, optical devices, etc., the high thermal expansion coefficient of tungsten alloy has become an advantage.

In summary, high-density tungsten alloy crankshaft counterweight is an engineering material of great value, widely used in many fields, and has broad application prospects.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595