Tungsten alloy plays a critical role in nuclear engineering. It is widely used in nuclear reactors, nuclear fuel rods, nuclear waste processing and other aspects. The various applications and data support of tungsten alloys in nuclear engineering will be introduced in detail below.

- Application in nuclear reactors

fuel rod support structure

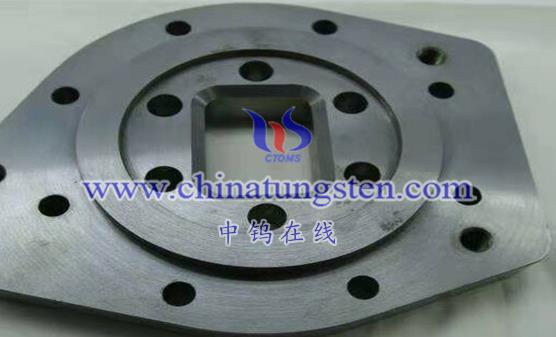

The application of tungsten alloy in nuclear reactors is first reflected in the fuel rod support structure. Fuel rods are the core components of a nuclear reactor and carry nuclear fuel, such as radioactive elements such as uranium or plutonium. Tungsten alloy’s high strength and corrosion resistance make it an ideal material for manufacturing fuel rod support structures.

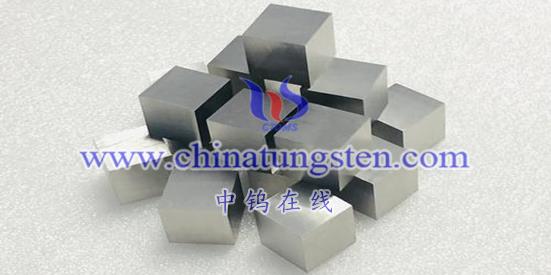

Data support: Tungsten alloy has extremely high tensile strength and hardness and can remain stable in high temperature and high pressure environments. According to relevant experimental data, the tensile strength of high-density tungsten alloy can reach 1800 MPa, and the hardness can reach about HB 300. This excellent mechanical property enables tungsten alloy to withstand the complex stress environment of the fuel rods in the reactor, ensuring the stability and reliability of the fuel rods.

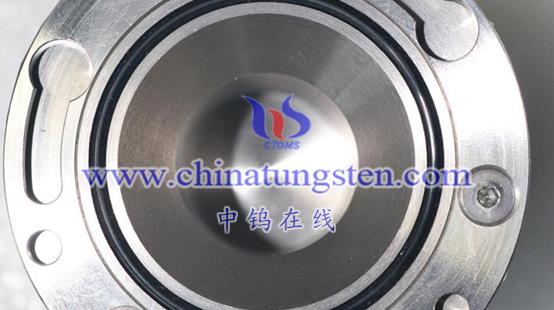

control rod drive mechanism

Tungsten alloys are also used to manufacture control rod drive mechanisms in nuclear reactors. Control rods are an important component used to control the rate of nuclear reactions. By adjusting the position of the control rods, the power output of the reactor can be controlled. The high strength and corrosion resistance of tungsten alloy make it an ideal material for drive mechanisms.

Data support: The high strength and good thermal stability of tungsten alloy enable it to withstand high temperature and high pressure environments. According to relevant experimental data, the tensile strength of high-density tungsten alloy can still maintain a high level at high temperatures, which enables the tungsten alloy to meet the working requirements of the control rod driving mechanism in high-temperature environments.

Reflective layer material

Tungsten alloys are also used as reflective layer materials in nuclear reactors. The function of the reflective layer is to reflect escaped neutrons back to the core of the reactor to improve the efficiency of the nuclear reaction. The high reflectivity and good thermal stability of tungsten alloy make it an ideal choice for reflective layer materials.

Data support: Tungsten alloy has high reflectivity and high thermal stability, which can effectively reflect escaping neutrons and maintain stability. According to relevant experimental data, the reflectivity of high-density tungsten alloy can reach more than 92%. At the same time, its high thermal stability allows it to remain stable in high-temperature environments, thereby improving the efficiency of nuclear reactions.

- Application in nuclear fuel rods

fuel pellet support

The application of tungsten alloy in nuclear fuel rods also includes the support structure of fuel pellets. Fuel pellets are the core part of nuclear fuel rods and are composed of radioactive elements such as uranium or plutonium. The high strength and corrosion resistance of tungsten alloys make it an ideal material for manufacturing fuel pellet support structures.

Data support: Tungsten alloy has extremely high tensile strength and hardness and can remain stable in high temperature and high pressure environments. According to relevant experimental data, the tensile strength of high-density tungsten alloy can reach 1800 MPa, and the hardness can reach about HB 300. This excellent mechanical property enables tungsten alloy to withstand the complex stress environment of the fuel pellets in the reactor, ensuring the stability and reliability of the fuel pellets.

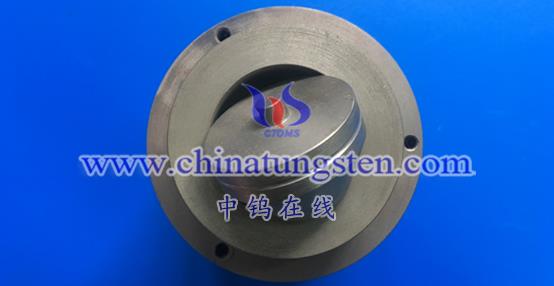

Fuel pellet packaging

Tungsten alloys are also used in nuclear fuel rods to manufacture the packaging structure of fuel pellets. The function of the packaging structure is to protect the fuel pellets from the external environment while ensuring the integrity and safety of the fuel pellets. Tungsten alloy’s high strength and corrosion resistance make it an ideal material for packaging structures.

Data support: Tungsten alloy has high strength and good corrosion resistance, which can ensure the stability and reliability of the packaging structure. According to relevant experimental data, the tensile strength of high-density tungsten alloys can still maintain a high level at high temperatures, which enables tungsten alloys to meet the working requirements of packaging structures in high-temperature environments.

- Application in nuclear waste treatment

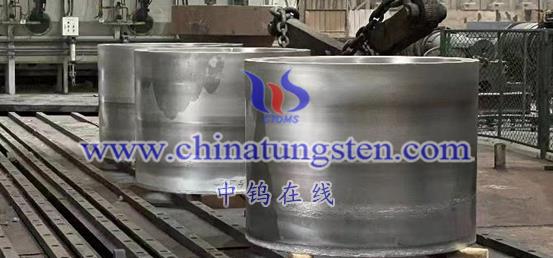

waste storage container

Tungsten alloys are also used in nuclear waste disposal to make waste storage containers. The role of storage containers is to safely store and handle nuclear waste and prevent it from causing harm to the environment and human health. Tungsten alloy’s high strength and corrosion resistance make it an ideal material for storage containers.

Data support: Tungsten alloy has high strength and good corrosion resistance, which can ensure the stability and reliability of storage containers. According to relevant experimental data, the tensile strength of high-density tungsten alloys can still maintain a high level at high temperatures, which enables tungsten alloys to meet the working requirements of storage containers in high-temperature environments. At the same time, the corrosion resistance of tungsten alloy also enables it to resist corrosion by chemicals in the waste, ensuring the long-term stability and safety of the storage container.

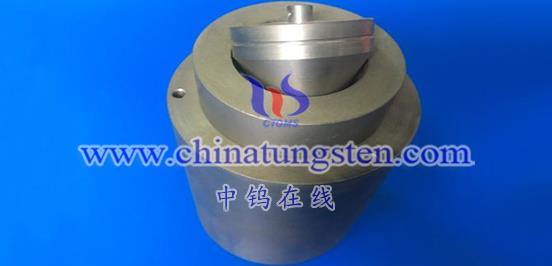

waste disposal equipment

Tungsten alloys are also used in nuclear waste disposal to make components in waste disposal equipment. These components need to withstand extreme environments such as high temperatures, high pressures, and strong radiation. They also require light weight and precise dimensions. The excellent properties of tungsten alloys can meet these requirements.

Data support: Tungsten alloy has high strength and high thermal stability, and can remain stable in high temperature and high pressure environments. According to relevant experimental data, the tensile strength of high-density tungsten alloys can still maintain a high level at high temperatures, which enables tungsten alloys to meet the working requirements of scrap processing equipment in high-temperature environments.

In addition, tungsten alloy also has good corrosion resistance and chemical stability, and can resist the corrosion of chemical substances in nuclear waste, ensuring the long-term stability and safety of processing equipment.

Data support: Tungsten alloys can still maintain high tensile strength and hardness in strong radiation and chemical corrosion environments. According to relevant experimental data, high-density tungsten alloys can still maintain high tensile strength in strong radiation and chemical corrosion environments. High level, which enables tungsten alloys to meet the working requirements of scrap processing equipment in these extreme environments.

- Future applications of tungsten alloys in nuclear engineering

With the continuous development of science and technology, the application prospects of tungsten alloy in nuclear engineering are becoming increasingly broad. In the future, tungsten alloy may be used in the following aspects:

Development of advanced nuclear energy systems: With the continuous development of nuclear energy technology, the research and development and experimentation of new nuclear energy systems will become an important direction in the field of nuclear engineering in the future. In these new nuclear energy systems, tungsten alloys can be used as structural and functional materials for high-temperature reactors, such as fuel rod support structures and reflective layer materials.

Nuclear waste treatment and radioactive waste management: With the increasing application of nuclear energy, nuclear waste treatment and radioactive waste management have become one of the focuses in the field of nuclear engineering. As a material with excellent properties, tungsten alloy can be used to manufacture high-strength, corrosion-resistant storage containers and waste treatment equipment, improving the efficiency and safety of radioactive waste treatment.

Manufacturing of Nuclear Safety and Protective Equipment: In the field of nuclear energy, the manufacturing of safety and protective equipment is crucial. As a material with excellent properties, tungsten alloy can be used to manufacture safety and protective equipment such as control rod driving mechanisms, containments and protective covers of nuclear reactors to improve the performance and reliability of the equipment.

In short, tungsten alloys play an important role in nuclear engineering and can improve the performance and reliability of nuclear engineering equipment while reducing costs and environmental pollution. With the continuous advancement of science and technology and the expansion of application fields, the application prospects of tungsten alloys in nuclear engineering will be broader.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten carbide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595