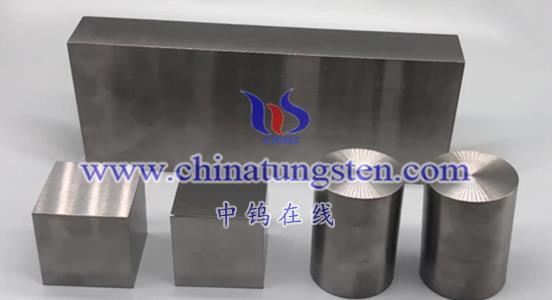

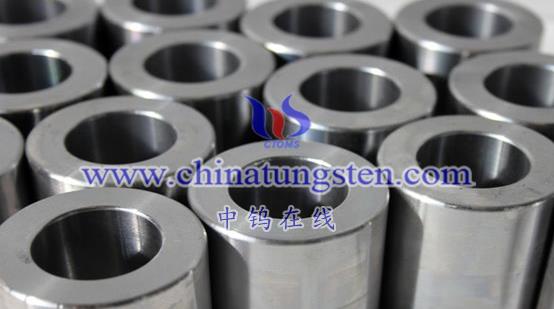

High-density tungsten alloy has good performance in aircraft engines. Due to its high density, high strength, high temperature resistance and oxidation resistance, tungsten alloy is widely used in the manufacturing of aircraft engines.

First of all, high-density tungsten alloy has high strength and good mechanical properties, and can maintain its mechanical stability in high-temperature environments and withstand the complex stress inside the aircraft engine. Secondly, tungsten alloy has excellent high temperature resistance and can maintain its structural and mechanical properties stable at extremely high temperatures, which helps improve the efficiency and performance of aircraft engines. In addition, tungsten alloy also has good oxidation resistance and can resist the effects of oxidation and corrosion in high temperature environments.

In aircraft engines, tungsten alloys are widely used in the manufacture of key components such as combustion chambers, turbine blades, guide vanes and nozzles. These parts need to withstand the impact of high temperature, high pressure and high-speed air flow, so they need to have high strength, high temperature resistance and oxidation resistance. The application of tungsten alloy can improve the performance and reliability of aircraft engines and reduce maintenance costs and risks.

In general, high-density tungsten alloy has good performance in aircraft engines, which can improve the efficiency and reliability of the engine and ensure the safety and economy of flight.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595