The manufacturing process of tungsten alloy balls involves a series of complex processes and technologies, which requires precise control of the composition of raw materials, processing conditions and heat treatment processes.

- Raw material preparation

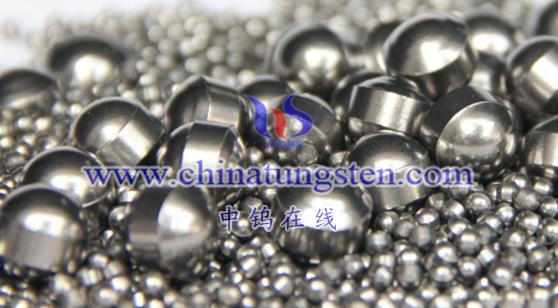

The raw materials required for manufacturing tungsten alloy balls mainly include tungsten powder, nickel powder, iron powder, copper powder and other metal powders. These powders require careful preparation and processing to ensure the uniformity and stability of their composition and organizational structure. Tungsten powder is the main component of tungsten alloy balls. Its particle size, purity and bulk density have an important impact on the manufacturing process and performance of tungsten alloy balls. Added elements such as nickel powder and iron powder are evenly dispersed in the tungsten powder, which helps to improve the mechanical properties and processing performance of the tungsten alloy ball.

- Mixing and pressing

Mixing tungsten powder, nickel powder, iron powder and copper powder according to a certain formula ratio is an important step in manufacturing tungsten-nickel-iron-tungsten alloy balls. During the mixing process, attention should be paid to controlling the particle size and distribution of the powder to ensure uniformity and stability of the mixing. The mixed powder is pressed and formed into a green body with a certain shape and size. The pressure and temperature need to be controlled during the pressing process to ensure the density of the green body and the stability of the tissue structure. Commonly used pressing methods include cold pressing and hot pressing.

- Sintering

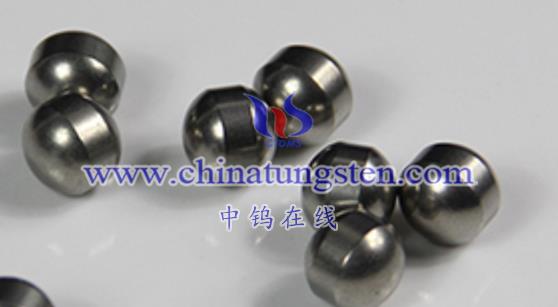

The pressed green body needs to be sintering, so that the tungsten-nickel-iron-tungsten alloy powder melts and solidifies at high temperature. The temperature and time need to be controlled during the sintering process to ensure the stability of the grain structure and mechanical properties of the tungsten alloy balls. The sintering temperature of tungsten alloy is usually close to the melting point of tungsten to achieve complete melting and diffusion between tungsten powder particles. During the sintering process, the gaps between the tungsten powder particles gradually disappear, forming dense tungsten alloy balls.

- Heat treatment and processing

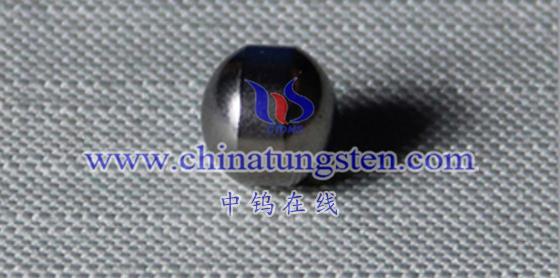

The sintered tungsten alloy balls need to be heat treated to eliminate internal stress and improve the hardness and wear resistance of the tungsten alloy balls. During the heat treatment process, tungsten alloy balls need to be heated and cooled within a certain temperature range to optimize their mechanical properties and stability. In addition, in order to meet the needs of different fields, tungsten alloy balls require surface treatment and processing. Surface treatment can enhance the corrosion resistance and aesthetics of tungsten alloy balls. The processing link can carry out finishing and surface treatment on tungsten alloy balls, such as grinding, polishing, etc.

- Quality inspection and packaging

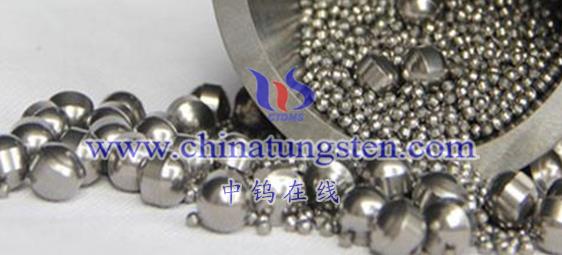

The manufactured tungsten alloy balls need to undergo strict quality inspection to ensure that they meet the predetermined quality requirements. Quality inspection includes appearance inspection, dimensional measurement, density test, hardness test and non-destructive testing. For qualified tungsten alloy balls, proper packaging and labeling are required for easy transportation and use. Packaging materials should have good moisture-proof, dust-proof and shock-proof properties to ensure the safety and stability of tungsten alloy balls during transportation and storage.

- Production control and environmental protection measures

In the manufacturing process of tungsten alloy balls, production control is crucial. Factories need to establish a complete quality management system to ensure the quality and stable supply of raw materials; at the same time, strengthen monitoring and testing of the production process to prevent the production of substandard products. In addition, in order to reduce energy consumption and reduce environmental pollution, effective environmental protection measures should be taken during the manufacturing process, such as waste gas treatment, noise control, etc. Factories should also actively promote cleaner production technologies and circular economy models to improve resource utilization efficiency and reduce production costs.

- Quality control and testing

In order to ensure that the performance and quality of tungsten alloy balls meet the requirements, strict quality control and testing are required during the manufacturing process. Quality control includes quality testing of raw materials, monitoring of the production process, and quality inspection of final products. The test involves the detection and evaluation of the physical properties, chemical composition, mechanical properties and other aspects of the tungsten alloy ball. Through quality control and testing, potential problems can be discovered and solved in time, improving product reliability and consistency.

- Production equipment and process optimization

Manufacturing tungsten alloy balls requires advanced production equipment and process technology. With the continuous development of science and technology, continuous optimization of production equipment and process technology is crucial to improving product quality and reducing production costs. By improving equipment performance, introducing intelligent technology, and optimizing process parameters, production efficiency and product quality can be improved, and the application fields of tungsten-nickel-iron-tungsten alloy balls can be further expanded.

To sum up, manufacturing iron-tungsten alloy balls is a process involving multiple links and complex technologies. In order to produce high-quality tungsten alloy balls, it is necessary to strictly control the quality of raw materials, processing conditions and heat treatment processes; at the same time, strengthen the application of production management and environmental protection measures. With the continuous development of science and technology, it is expected that the manufacturing process and technology will be further optimized in the future, and the performance and application range of tungsten alloy balls will be improved.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595