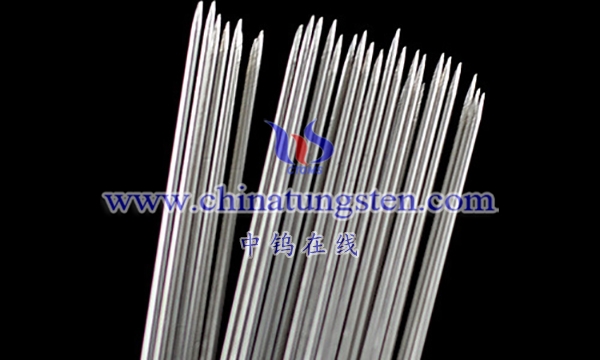

Tungsten needle is a slender metal product with a high melting point made of pure tungsten. It is widely used in fields such as electronics, electrical engineering and aerospace, and is commonly used as electrodes, spark plugs and heating elements in high temperature applications. The following is the production process of tungsten pins, no less than 3,000 words:

1. Raw material preparation

The first step in producing tungsten pins is to prepare raw materials. The main raw material of tungsten pins is tungsten powder, which is usually made by chemical deposition or mechanical ball milling. In order to ensure the purity and particle size of tungsten powder, a series of chemical treatments and grinding processes are generally performed. Next, the tungsten powder is dried and placed at high temperatures for pre-oxidation treatment to increase its fluidity.

2. Press forming

The pre-oxidized tungsten powder is put into the mold and pressed under high pressure. In this process, tungsten powder is bonded together under pressure to form a tungsten billet with a certain shape and size.

3. Degreasing

The pressed tungsten blank contains a large number of impurities and pores, so it needs to be degreased. Degreasing is accomplished by heating the tungsten billet in a vacuum so that impurities and gases in the pores are driven out. This step can further purify the tungsten billet and improve its purity.

4. Sintering

Sintering is one of the key steps in the tungsten needle production process. In this process, the tungsten billet is heated at high temperatures for a long time to homogenize the density of each part and enhance its mechanical properties. Sintering is usually carried out in a high temperature furnace or plasma furnace.

5. Processing and heat treatment

The sintered tungsten needle requires a series of processing and heat treatment. First, use a cutting machine to cut the tungsten needle to the desired length. Then grind it to remove surface burrs and uneven areas to ensure that the surface of the tungsten needle is smooth. Finally, heat treatment is performed to adjust the hardness and toughness of the tungsten needle by controlling the heating temperature and time.

6. Quality inspection

After the above steps, the tungsten needle needs to be inspected for quality. The testing content includes dimensional accuracy, surface quality, composition analysis, etc. Qualified products can enter the next process, while unqualified products need to be returned for reprocessing or scrapped.

7. Packaging and transportation

Tungsten pins that pass quality inspection need to be packaged and transported. Dust-proof packaging is usually used to avoid contamination of tungsten pins during transportation. Packaged tungsten pins can be shipped to customers or stored in the warehouse for future use.

8. Application

Tungsten pins are widely used in electronics, electrical engineering, aerospace and other fields because of their high melting point and excellent electrical conductivity. In the electronics industry, tungsten pins are used as heating elements and electrodes in vacuum tubes, electron tubes, transistors and other devices. In electrical engineering, tungsten pins are used as electrodes and switching devices in high-voltage circuits. In the aerospace field, tungsten pins are used to manufacture key components in rocket engines due to their high melting point and excellent corrosion resistance. In addition, tungsten pins can also be used to manufacture heating elements in high-temperature furnaces and additives in tool steel.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595