The production process of forged tungsten bars consists of multiple steps. First, tungsten metal needs to be processed into strips. This process may involve cutting, grinding and other steps. The tungsten strip then needs to be heated to a certain temperature and forged to increase its density and hardness. This process may need to be repeated several times to ensure that the density and hardness of the tungsten strip meet the requirements. Finally, the tungsten strip needs to be cooled and processed to conform to the size and shape requirements of the final product.

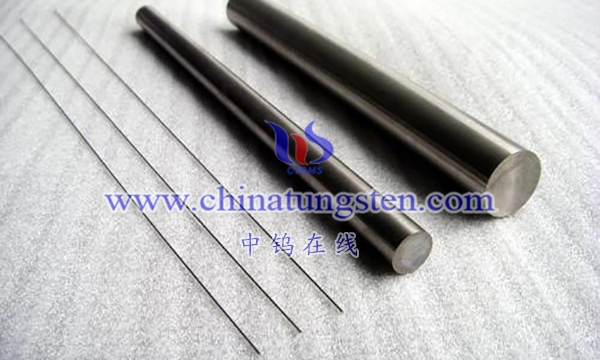

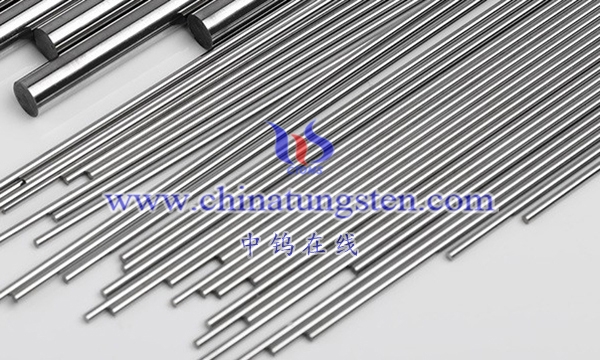

Forged tungsten bar is a bar-shaped material made of tungsten metal, which has the advantages of high density, high hardness, high tensile strength and good corrosion resistance. It has wide applications in many fields, such as aerospace, electronics, national defense, nuclear industry, etc. The production process of forged tungsten bars will be introduced in detail below.

1. Raw material preparation

The production of forged tungsten bars first requires the preparation of raw materials, namely tungsten metal. Tungsten metal usually exists in the form of tungsten powder or tungsten strips, and its purity requirements are very high, generally reaching more than 99.95%. In order to ensure the purity and quality of tungsten metal, a series of chemical treatments and grinding processes are required. These processes include selection, drying, smelting, ingot casting, annealing and grinding.

2. Forging and forming

Forging forming is a key step in the production process of forged tungsten bars. In this process, tungsten metal is heated to a certain temperature and forged repeatedly to increase its density and hardness. Forging is usually performed in a high temperature and high-pressure environment, using specialized forging equipment and tools. During the forging process, attention needs to be paid to controlling the heating temperature and time, as well as the intensity and frequency of forging, to ensure that the density and hardness of tungsten metal meet the requirements.

3. Cooling treatment

The forged tungsten bars need to be cooled to prevent them from deforming or cracking. The cooling process usually uses slow cooling to maintain the shape and quality of the tungsten strip. At the same time, certain processing is required during the cooling process, such as straightening, cutting, etc., so that the size and shape of the tungsten strip meet the requirements.

4. Quality inspection

After the above steps, the quality of the forged tungsten bars needs to be inspected. The testing content includes appearance quality, dimensional accuracy, density and hardness, etc. Quality inspection is an important step to ensure that forged tungsten bars meet the requirements, so the quality and accuracy requirements of each link need to be strictly controlled.

5. Application

Forged tungsten bars have the advantages of high density, high hardness, high tensile strength and good corrosion resistance, so they are widely used in many fields. In the aerospace field, forged tungsten bars are used to manufacture high-performance components such as aircraft engine blades and spacecraft casings. In the electronics field, forged tungsten strips are used to manufacture heating elements and electrodes in electron tubes, transistors and other devices. In addition, forged tungsten bars are also used to manufacture nuclear reactor components in the nuclear industry, lenses in electron microscopes, etc.

In short, the production process of forged tungsten bars involves multiple steps and complex process technology, which requires corresponding professional technology and equipment for production. At the same time, due to the rarity and high value of tungsten metal, the production cost of forged tungsten bars is high and the price is relatively expensive. However, due to its excellent performance and wide application prospects, forged tungsten bars are still a very important material with broad market prospects and development potential.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595