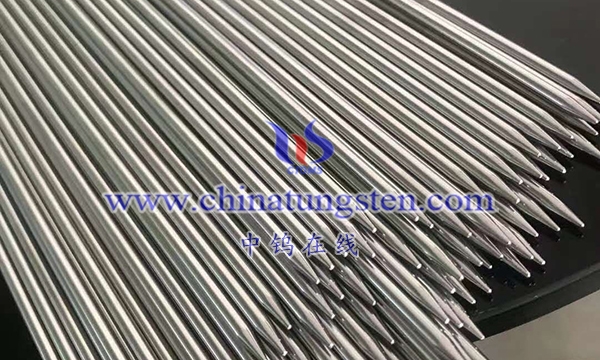

A tungsten needle is a slender metal rod made of tungsten, commonly used as a heating element in vacuum tubes, electronic devices, high-temperature furnaces, etc. Tungsten needle pins have a series of excellent physical and chemical properties, among which corrosion resistance is an important aspect.

First, tungsten needle pins have excellent corrosion resistance. In the field of chemistry, many metals and alloys are prone to corrosion damage in acids, alkalis or other corrosive media. However, tungsten needle pins show good resistance in these corrosive media. This is due to the high density, high melting point and high chemical stability of tungsten needle pins.

Secondly, tungsten needle pins also have good corrosion resistance in high temperature environments. At high temperatures, many metals and alloys undergo reactions such as oxidation, sulfidation, or chlorination, leading to corrosion damage. However, tungsten needle pins exhibit good oxidation resistance and corrosion resistance in high temperature environments. This is due to the formation of a dense oxide film on the surface of the tungsten needle, which can effectively prevent further oxidation. In addition, tungsten needle pins also have high-temperature stability and chemical stability, allowing them to maintain long-term corrosion resistance in high-temperature environments.

In addition, tungsten needle pins also have good fatigue resistance. Under the action of alternating stress, many metals and alloys will undergo fatigue fracture. However, due to its high density, high melting point and good corrosion resistance, tungsten needle pins exhibit good fatigue resistance under alternating stress. This makes tungsten needle pins very suitable for applications that are subject to alternating stress.

Tungsten needle pins have excellent corrosion resistance. Whether in corrosive media such as acids and alkalis or in high-temperature environments, tungsten needle pins show good tolerance and stability. These excellent physical and chemical properties make tungsten needle pins an ideal material choice in many fields.

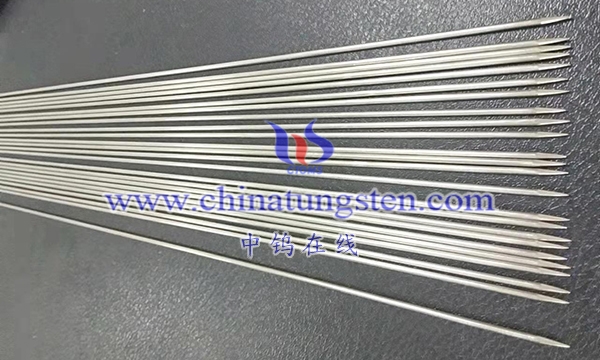

However, it should be noted that although the tungsten needle has good corrosion resistance, it may still be damaged by corrosion in some specific corrosive environments. Therefore, when using tungsten needle pins, it is necessary to select appropriate materials and processes according to specific conditions to ensure that they maintain good corrosion resistance during use.

For situations where the corrosion resistance of tungsten needle pins needs to be improved, some surface treatment techniques can be used to enhance their corrosion resistance. For example, the corrosion resistance of the tungsten needle can be improved by coating the surface of the tungsten needle with a corrosion-resistant coating (for example, the coating material is chromium, nickel, etc.) and performing surface alloying treatment. These surface treatment technologies can effectively enhance the corrosion resistance of tungsten needle pins and extend their service life.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595