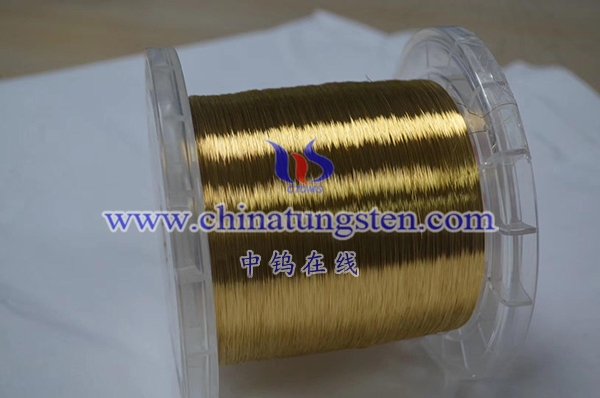

The difficulties and precautions in the manufacturing process of gold-plated tungsten wire mainly include the following aspects:

Preparation of tungsten wire

Tungsten is a metal with high melting point and high density. The preparation process requires multiple processes, such as material selection, smelting, forging, drawing, etc. Each process requires strict control of process parameters to ensure the purity of tungsten wire. Properties such as strength and elasticity.

Surface treatment

There are impurities and oxide layers on the surface of tungsten wire, and surface treatment is required to enhance the adhesion and uniformity of the coating. Surface treatment can use chemical etching, mechanical grinding, electrochemical polishing and other methods, but these methods require strict control of treatment time and treatment concentration to prevent excessive treatment from causing surface damage to the tungsten wire.

Gold plating process

The gold plating process is one of the core links in the manufacturing of gold-plated tungsten wire. Parameters such as current, time, and temperature need to be controlled to ensure the thickness and uniformity of the gold coating. The thickness of the gold coating should be moderate. If it is too thin, the protective effect will be poor, and if it is too thick, the cost will increase. In addition, the environment must be kept clean during the gold plating process to prevent the introduction of impurities and pollutants.

Post-processing

After the gold-plated tungsten wire is manufactured, post-processing is required, such as cleaning, drying, etc., to remove excess chemical reagents and moisture to ensure the quality and performance of the product. During the post-processing process, it is necessary to avoid over-processing that may cause damage or peeling of the coating, and at the same time, ensure that the cleaning fluid is clean and pure.

Quality inspection and packaging

Gold-plated tungsten wire requires quality testing, including appearance testing, performance testing, etc., to ensure that the quality and performance of the product meet the requirements. The packaging should prevent the product from being damaged and contaminated, while ensuring the sealing and protective effect of the packaging.

Safety and environmental protection

Safety and environmental issues need to be paid attention to during the manufacturing process of gold-plated tungsten wire. Operators need to receive professional training and abide by operating procedures and safety regulations to avoid accidents. At the same time, attention should be paid to environmental protection and resource recycling issues during the manufacturing process, to reduce the generation of waste gas, waste water and waste residue, and to achieve green manufacturing.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595