The gold plating process of gold-plated tungsten wire mainly includes the following steps:

- Preparation stage

In the preparation stage, the tungsten wire needs to undergo necessary processing to smooth its surface and remove impurities. This typically includes steps such as pickling, sanding, and ultrasonic cleaning. These processing steps are designed to ensure that the tungsten wire surface is clean so that good adhesion and uniform plating can be achieved during the subsequent gold plating process.

- Chemical gold plating

Electroless gold plating is a method of depositing gold on the surface of tungsten wire through a chemical reaction. In this process, the tungsten wire is immersed in a chemical solution containing gold, and then the gold ions are reduced to metallic gold through a chemical reaction and deposited on the surface of the tungsten wire. This process usually includes the following steps:

- Acid dipping: Dip the tungsten wire into an acid solution to remove oxides and impurities on the surface and roughen the surface to increase adhesion.

- Activation: Use activator to activate the surface of tungsten wire to increase its adhesion to gold.

- Chemical gold plating: Put the tungsten wire into a chemical solution containing gold, and control the pH value and temperature of the solution to reduce the gold ions to metallic gold on the surface of the tungsten wire and deposit it.

- Stabilization treatment: Improve the stability and corrosion resistance of the gold plating layer through stabilization treatment, such as passivation or heat treatment.

- Physical gold plating

Physical gold plating is a method of plating gold on the surface of tungsten wire through physical means. This method usually uses vacuum evaporation or electroplating. During this process, gold atoms are evaporated or ionized and then deposited on the surface of the tungsten wire. The physical gold plating process usually includes the following steps:

- Cleaning: Clean the surface of the tungsten wire to remove impurities and oxides.

- Pretreatment: Use a pretreatment agent to pretreat the surface of the tungsten wire to increase its adhesion to gold.

- Gold plating: gold atoms are deposited on the surface of tungsten wire in a vacuum or using electroplating.

- Stabilization treatment: Improve the stability and corrosion resistance of the gold plating layer through stabilization treatment, such as passivation or heat treatment.

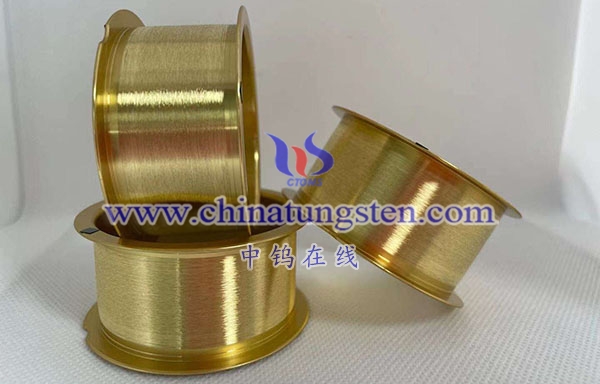

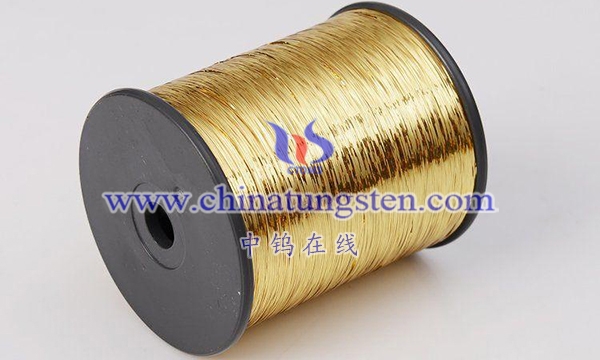

- Post-processing stage

In the post-processing stage, the gold-plated tungsten wire needs to be treated as necessary to make it meet the needs of use. This usually includes steps such as cutting, winding, inspection and packaging. These processing steps are designed to ensure the quality and safety of gold-plated tungsten wire.

In general, the gold plating process of gold-plated tungsten wire is a complex and delicate process, which requires strict control of the process parameters and operating methods of each step to ensure a high-quality, high-stability gold plating layer. At the same time, the various chemical reagents and physical equipment used in this process also require strict maintenance and management to ensure the safety and stability of production.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595