90WMoNiFe alloy is an important metal alloy, mainly composed of tungsten, molybdenum, nickel and iron. Among them, tungsten is a high melting point metal with high strength, high hardness and corrosion resistance, and is the main reinforcing element of the alloy; molybdenum has good toughness and corrosion resistance, which can improve the ductility and wear resistance of the alloy; nickel It is a metal with good toughness and corrosion resistance, which can improve the ductility and wear resistance of the alloy; iron, as the base metal of the alloy, provides the alloy with good processability and mechanical properties.

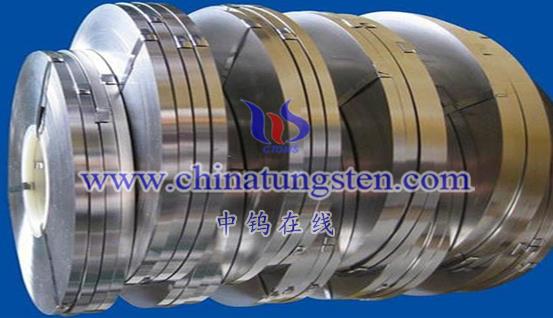

90WMoNiFe alloy is a unique alloy material. It is composed of tungsten as a matrix and a small amount of nickel, iron, molybdenum and other alloying elements. The alloy is produced using powder metallurgy and has a range of compelling physical and chemical properties.

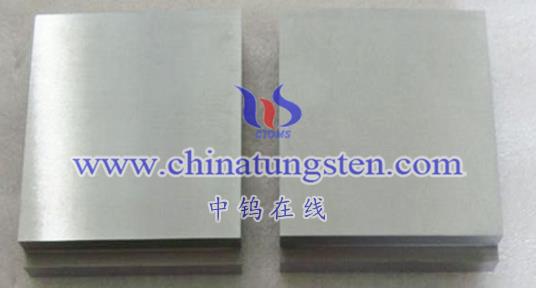

First, 90WMoNiFe alloy has a low expansion coefficient. This means that its volume changes relatively little when the temperature changes, so it can maintain high dimensional stability. This characteristic makes it have significant advantages in applications that require precise size control, such as precision instruments, electronic equipment, etc.

Secondly, the alloy also has high thermal conductivity. Thermal conductivity is an important parameter to measure the thermal conductivity of materials. High thermal conductivity means that the material can transfer heat more efficiently. Therefore, 90WMoNiFe alloy has broad application prospects in situations where efficient heat dissipation is required, such as electronic components and engine parts in high-temperature working environments.

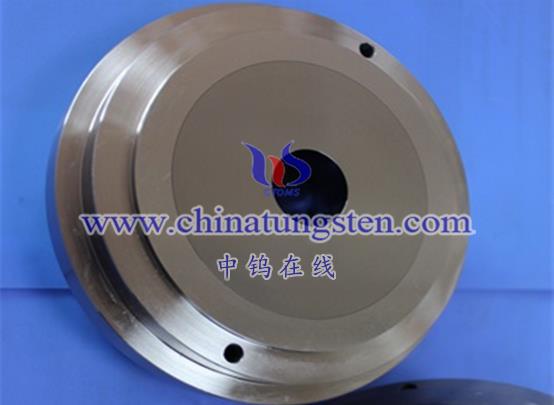

In addition, 90WMoNiFe alloy also exhibits good red hardness. Red hardness refers to the material’s ability to maintain its hardness at high temperatures, which is critical for materials working in high-temperature environments. Therefore, the alloy is widely used in high-temperature working parts such as anvils in the field of hot forging valves.

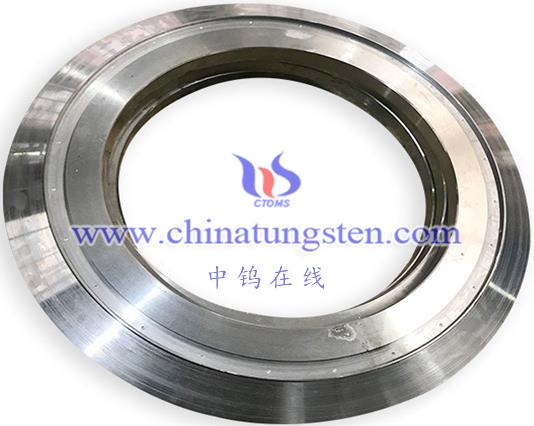

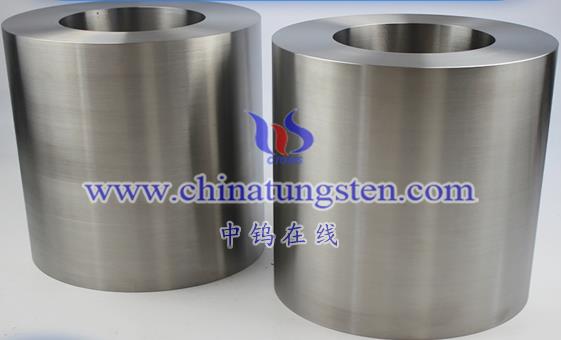

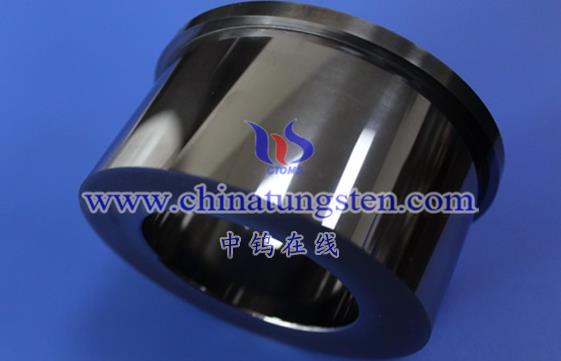

In terms of application fields, 90WMoNiFe alloy is widely used in the field of die-casting molds due to its unique properties. In addition, due to its excellent overall high-temperature properties, the alloy is also used as a hot riveting bearing material. Especially in the field of hot stamping valves, 90WMoNiFe alloy has become an ideal material for making electric anvil blocks for valve stamping because of its high thermal conductivity and high-temperature performance. The use of this material can significantly increase the service life of the anvil block and reduce production costs.

From the perspective of production technology, the production process of 90WMoNiFe alloy is strictly implemented in accordance with ISO 9001 quality standards, ensuring stable product quality and performance. At the same time, the tungsten-based high specific gravity alloy materials produced fully comply with the specifications of AMS-T-21014 and ASTM-B-777-99 (MIL-T-21014), which further proves its recognition and reliability in the industry .

In general, 90WMoNiFe alloy is a material with excellent physical and chemical properties. Its wide range of applications and reliable production processes make it occupy an important position in modern industry. With the advancement of science and technology and the continuous improvement of technology, it is believed that 90WMoNiFe alloy will have broader application prospects in the future.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595