The JET Tokamak device is a ring-shaped vacuum chamber device called “Tokamak”. It is driven by constrained electromagnetic waves to create an environment and ultra-high temperature for deuterium and tritium to achieve fusion, and realizes human control of the fusion reaction. Its name comes from the prefix combination of toroidal, kamera, magnet and kotushka.

The core of the JET tokamak device is a ring-shaped vacuum chamber with coils wrapped around the outside. When it is powered on, a huge spiral magnetic field will be generated inside, heating the gas in the vacuum chamber to extremely high temperatures, such as 150 million degrees Celsius, and trapping the plasma in the inner wall of the device to achieve the purpose of nuclear fusion. This device is particularly unique because it is the only tokamak capable of trapping a deuterium-tritium mixture. Two hydrogen elements, deuterium and tritium, may help turn the process of releasing energy from nuclear fusion into a sustainable process with an energy surplus.

The JET Tokamak device is located at the Callum Fusion Energy Center in Oxfordshire, UK, and is operated by the European Fusion Energy Development Consortium. Not only is it one of the largest tokamak devices in the world, it is also regarded as an important test bed for ITER (International Thermonuclear Experimental Reactor Program). The ITER project is jointly implemented by China, the European Union, India, Japan, South Korea, Russia and the United States, and aims to build the world’s largest tokamak device in southern France.

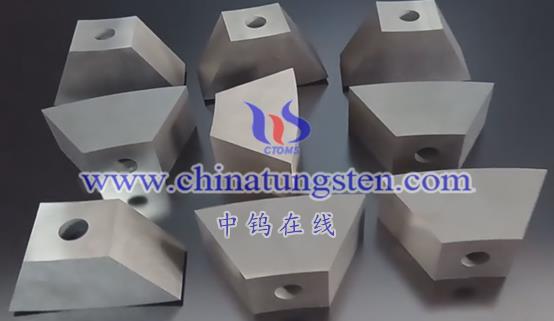

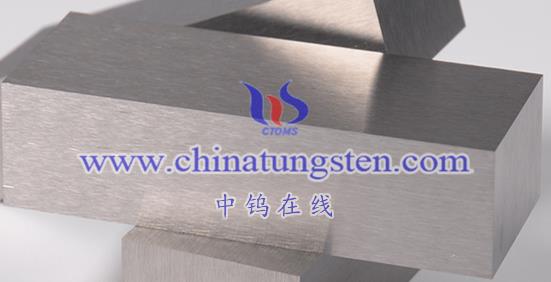

The application of 90WMoNiFe alloy in the European JET (Joint European Torus) tokamak device is mainly focused on the manufacturing of plasma-facing components and structural materials. JET is a large-scale nuclear fusion research device designed to simulate the nuclear fusion process inside the sun and study the conditions and mechanisms of nuclear fusion reactions.

First of all, 90WMoNiFe alloy is used to manufacture components in JET devices that directly face high-temperature plasma due to its excellent high temperature resistance and corrosion resistance. These components need to withstand extremely high temperatures and intense particle flow impacts, and 90WMoNiFe alloys can maintain structural stability and integrity under such extreme conditions. This makes the alloy an ideal material for critical components such as the first wall and divertor, effectively protecting other components from the high-temperature plasma.

Secondly, 90WMoNiFe alloy is also used to make structural materials in JET devices. Since a large amount of heat and radiation are generated during the nuclear fusion reaction, structural materials need to have good thermal conductivity and radiation resistance. The excellent properties of 90WMoNiFe alloy enable it to meet these requirements and ensure the structural stability and safe operation of the device.

In addition, 90WMoNiFe alloy may also be used in neutron shielding and radiation protection. Nuclear fusion reactions produce neutrons and other radiation, posing potential threats to equipment and personnel. Using the high density and good radiation protection properties of 90WMoNiFe alloy, neutron shielding structures and radiation protection layers can be manufactured to effectively reduce radiation damage to equipment and personnel.

With the deepening of nuclear fusion research and the continuous advancement of technology, the application of 90WMoNiFe alloy in JET devices may be further optimized and improved based on experimental needs and technological development. Therefore, future research may explore more about the application potential and possibilities of this alloy in JET devices.

In summary, 90WMoNiFe alloy plays an important role in the European JET Tokamak device. Its high temperature resistance, corrosion resistance, thermal conductivity and radiation resistance make it an ideal choice for plasma-facing components and structural materials. .

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595