China’s Eastern Advanced Superconducting Tokamak (EAST) is a fully superconducting tokamak nuclear fusion experimental device designed and developed by my country. Its completion marks that China has begun to lead magnetic confinement fusion in the physics and engineering of steady-state operation. The international forefront of research, becoming the first country to master a new generation of advanced all-superconducting tokamak technology.

The Oriental Hyperloop is China’s major achievement in the field of fusion energy research. It not only demonstrates China’s strong strength in the field of science and technology, but also opens up a new path for mankind to find ideal clean energy in the future.

In September 2006, Oriental Hyperloop successfully completed the discharge experiment for the first time, obtaining a high-temperature plasma discharge with a current of 200 kA and a duration of nearly 3 seconds, making it the first and only fully superconducting non-circular cross-section in the world that was built and actually operated. Nuclear fusion experimental device. In the 16th round of physical experiments in May 2021, the Oriental Hyperloop achieved repeatable 120 million degree 101 second plasma operation and 160 million degree 20 second plasma operation, setting a new world record for operation.

The successful construction and operation of the Oriental Hyperloop not only reflects China’s strength in the field of fusion energy research, but also provides scientific and engineering support for the future International Thermonuclear Fusion Experimental Reactor (ITER) to achieve steady-state high-confinement discharge. Its series of innovative research results and technology accumulation have provided a solid scientific and engineering foundation for my country to build its own Eastern Hyperloop.

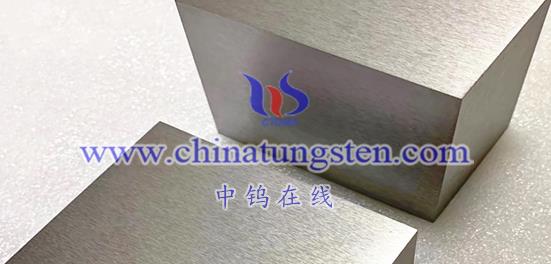

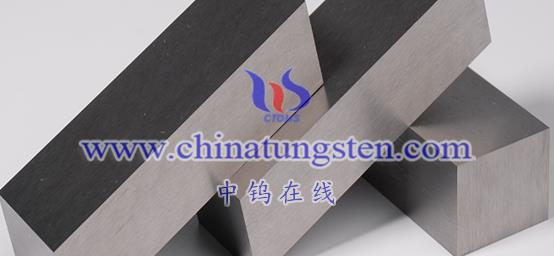

In China Oriental Super Ring, 90WMoNiFe alloy also plays an indispensable role. EAST is a fully superconducting tokamak device designed to explore the cutting-edge technology of nuclear fusion energy. Its goal is to achieve long-term steady-state operation of high-temperature plasma.

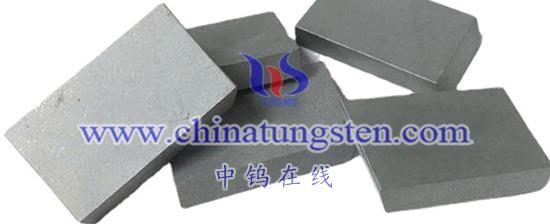

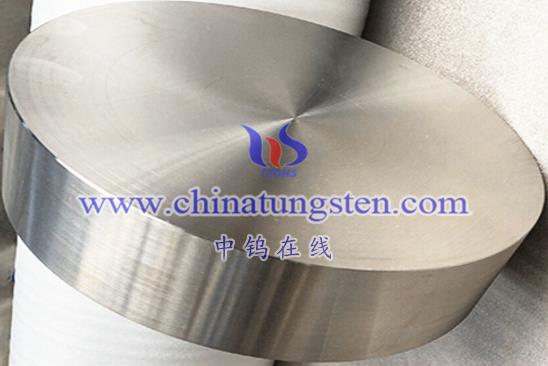

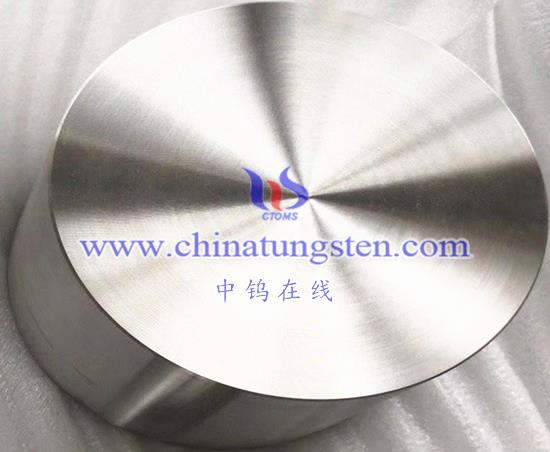

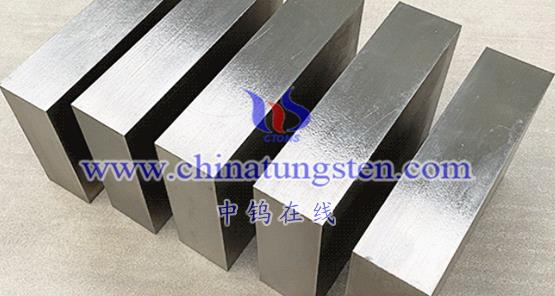

In EAST, 90WMoNiFe alloy is mainly used in the manufacture of plasma-facing components, especially the first wall and divertor. These components directly face high-temperature, high-density plasma and therefore need to withstand extreme thermal loads, particle flow impact, and radiation damage. 90WMoNiFe alloy has become an ideal material for manufacturing these key components due to its excellent high temperature resistance, corrosion resistance and radiation resistance.

Specifically, the first wall made of 90WMoNiFe alloy can effectively withstand the high temperature and particle impact of the plasma, maintaining the stability and integrity of its structure. At the same time, the divertor is made of 90WMoNiFe alloy, which can efficiently remove impurities and heat from the plasma, maintain the purity and stability of the plasma, and thereby improve the efficiency of the fusion reaction.

In addition, 90WMoNiFe alloy may also be used for other structural components and support structures in EAST. These components also need to withstand the effects of high temperature, high pressure and radiation, and the excellent properties of 90WMoNiFe alloy can ensure the reliability and safety of these components under extreme conditions.

With the in-depth progress of the EAST experiment and the continuous development of fusion technology, the requirements for material performance are also constantly increasing. Therefore, researchers may continue to explore more application potentials of 90WMoNiFe alloys in EAST, providing stronger support for the realization of nuclear fusion energy by optimizing and improving material properties.

In short, 90WMoNiFe alloy plays a key role in China’s Eastern Hyperring. Its excellent performance enables EAST to operate stably in high-temperature and high-density plasma environments, providing an important guarantee for the exploration of nuclear fusion energy.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595