Tokamak device T-1 (the word Tokamak is the abbreviation of the Russian words ring (тороидальная), cavity (камера), magnetic (магнитными) and coil (катушками)).

Tokamak is a ring-shaped vessel that uses magnetic confinement to achieve controlled nuclear fusion. Its name comes from toroidal (toroidal), vacuum chamber (kamera), magnet (magnit) and coil (kotushka). The device was originally invented in the 1950s by Azimovich and others at the Kurchatov Institute in Moscow, the Soviet Union.

The main body of the tokamak device is an annular vacuum chamber, which is used to form the closed vacuum conditions required for plasma confinement discharge. A longitudinal field magnet coil is wound around the outside of the vacuum chamber to form a ring-shaped main confinement magnetic field. At the same time, the device is equipped with multiple sets of poloidal field coils along the direction of the large ring to form the external poloidal field required to balance the plasma. Under the action of these magnet coils, a stable confinement zone can be formed inside the vacuum chamber to maintain the discharge operation of the plasma.

In the tokamak device T-1, 90WMoNiFe alloy plays an important role as a high-performance material. The T-1 tokamak device is designed to study magnetic confinement fusion plasma physics and explore the possibility of nuclear fusion reactions through long-term stable operation of high-temperature plasma.

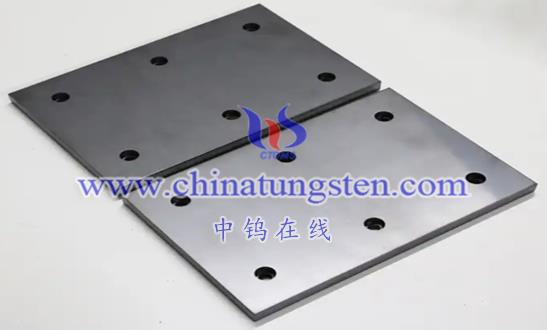

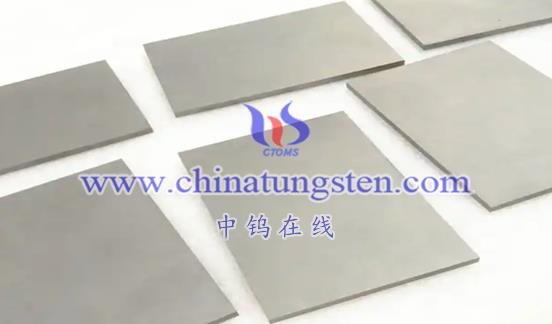

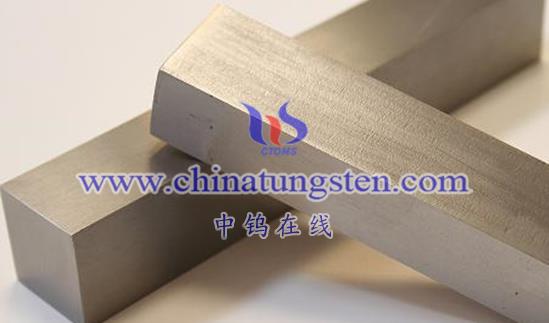

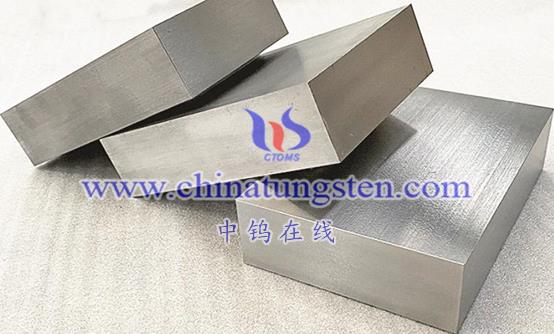

First, one of the key applications of 90WMoNiFe alloy in the T-1 is as a material for plasma-facing components. Plasma-facing components, such as the first wall and divertor, are directly exposed to high-temperature, high-density plasma environments and need to withstand extremely high thermal loads and particle flow impacts. 90WMoNiFe alloy is ideal for manufacturing these components due to its excellent resistance to high temperatures, corrosion and radiation. It can maintain the stability and integrity of the structure and ensure stable operation for a long time.

Secondly, 90WMoNiFe alloy is also used to manufacture support structures and fixtures in the T-1. During the fusion reaction process, the plasma confinement structure needs to be stably fixed and supported to ensure the stability of the plasma and reaction efficiency. The high strength and good mechanical properties of 90WMoNiFe alloy make it an ideal material for manufacturing these support structures and fixtures.

In addition, 90WMoNiFe alloy may also be used in other key components and structures in T-1, such as heat shields, diagnostic windows, etc. These components also need to withstand the effects of high temperature, high pressure and radiation, and the excellent properties of 90WMoNiFe alloy can ensure their reliability and safety under extreme conditions.

It is worth mentioning that with the deepening of nuclear fusion research and the continuous advancement of technology, the requirements for material performance are also constantly increasing. Therefore, in response to the specific needs of the T-1 device, researchers may further optimize and improve the 90WMoNiFe alloy to improve its performance and reliability in the device.

In summary, 90WMoNiFe alloy plays an important role in the tokamak device T-1 and is mainly used in the manufacturing of key components such as plasma-facing components, support structures and fixtures. Its excellent performance provides strong support for the stable operation of the T-1 device and the in-depth development of nuclear fusion research.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595