90WMoNiFe alloy is widely used in controlled nuclear fusion devices, and its excellent physical and chemical properties make it an ideal material for key components in these devices. The following are some specific application examples:

Plasma facing parts

In a controllable nuclear fusion device, components such as the first wall and divertor directly face high-temperature, high-density plasma. These components are subject to extremely high thermal loads, particle flow impacts, and radiation damage. 90WMoNiFe alloy has become the material of choice for manufacturing these components due to its excellent high temperature resistance, corrosion resistance and radiation resistance. It can operate stably for a long time, maintaining structural integrity and performance stability, thereby ensuring the continued progress of the fusion reaction.

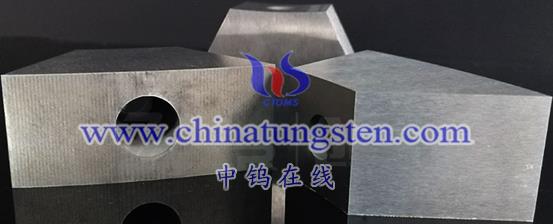

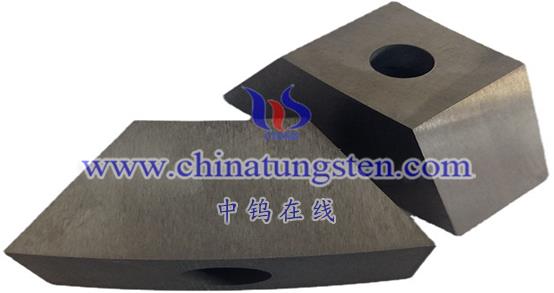

structural supports

Structural supports in controlled nuclear fusion devices need to withstand the weight of the device and various forces generated during operation. At the same time, these supports also need to maintain stability in high temperature, high pressure and radiation environments. The high strength, good mechanical properties and excellent thermal stability of 90WMoNiFe alloy enable it to meet these harsh working conditions and ensure the structural safety and stable operation of the fusion device.

heat shield

In fusion reactions, large amounts of heat need to be removed efficiently to prevent the device from overheating. 90WMoNiFe alloy can be used as a material for the heat shielding layer. It can quickly conduct heat to the cooling system through its good thermal conductivity, thereby maintaining a stable temperature inside the device.

diagnostic window

In order to monitor the status of the fusion reaction in real time, the device is usually equipped with a diagnostic window. 90WMoNiFe alloy can be used as a material for these windows because it can withstand the effects of high temperatures and radiation while remaining transparent enough for observation.

coils and magnets

In magnetic field confinement fusion devices, coils and magnets are key components to generate and maintain strong magnetic fields. 90WMoNiFe alloy can be used as the conductive material for these components because it has good electrical conductivity and thermal stability, which can ensure the stability and durability of the magnetic field.

In summary, 90WMoNiFe alloys are widely used and important in controlled nuclear fusion devices. They play key roles in plasma-facing components, structural supports, heat shields, diagnostic windows, and coils and magnets. effect. With the continuous development of fusion technology, the application prospects of 90WMoNiFe alloy will be broader.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595