What is CFETR engineering reactor?

CFETR (China Fusion Engineering Test Reactor), the Chinese Fusion Engineering Test Reactor, is a key facility designed by China to achieve its fusion energy goals. The goal of this project is to carry out the engineering concept design of my country’s fusion engineering experimental reactor on the basis of absorbing and digesting the key technologies for the design of advanced magnetic confinement fusion devices, and to conduct the integrated design of the fusion reactor and the research and development of its key technologies.

The main application scenarios of CFETR are concentrated in the field of nuclear fusion energy research. By simulating the nuclear fusion process inside the sun, the device aims to achieve controlled nuclear fusion reactions to provide humans with a clean, efficient and virtually unlimited energy supply. In addition, CFETR also provides a valuable experimental platform for research in plasma physics, materials science and other related fields.

In the design and construction of CFETR engineering reactor, advanced materials such as 90WMoNiFe alloy play an important role. These materials are widely used in divertors, structural materials, heat sink materials, and neutron shielding materials due to their unique physical and chemical properties. Their excellent performance helps ensure that CFETR can operate stably in extreme environments, thereby promoting the in-depth development of nuclear fusion energy research.

In addition, CFETR engineering reactor also focuses on international cooperation and exchanges. By cooperating with colleagues in the field of international fusion energy research and sharing experience and technology, the research and development process of CFETR can be accelerated and the common progress of global fusion energy research can be promoted.

Key technologies for nuclear fusion device design of CFETR engineering reactor

The key technologies for the design of the nuclear fusion device of the CFETR engineering reactor involve many aspects, which together constitute the complex system required to realize the fusion reaction. Here is an overview of some key technologies:

Host design technical parameter requirements

This is the basis for ensuring that the fusion device can operate stably and achieve the design goals. It covers aspects such as the overall layout, structure, material selection, and design of key components of the device.

Superconducting magnet system concept design

Superconducting magnet systems are the core part of fusion devices and are used to generate powerful magnetic fields to confine high-temperature plasmas. Its design involves the selection of superconducting materials, optimization of the magnet structure, and design of the cooling system.

Vacuum chamber, Dewar and cold screen design

The design of these components is critical to the performance and stability of fusion devices. The vacuum chamber is required to ensure the purity of the internal environment, while Dewars and cold screens are used to maintain a low-temperature environment inside the device to reduce heat loss.

Interior component concept design

Including the design of key components such as divertor, heating system, and diagnostic system. The performance of these components directly affects the effectiveness of the fusion reaction and the safety of the device.

Concept design of remote operating system

Because fusion devices operate in extreme environments, they require remote operation and monitoring through teleoperation systems. This involves sophisticated machinery, electronics and communications technology.

Assembly and system concept design

This covers the design of the entire fusion device assembly process, system integration and debugging.

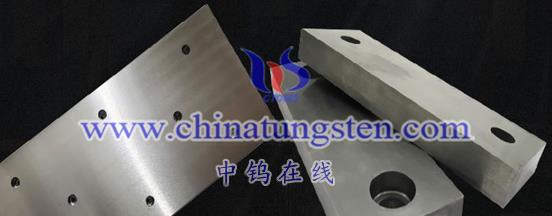

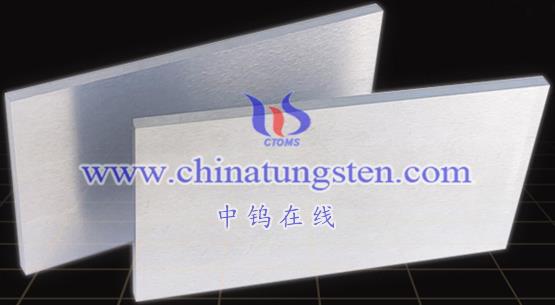

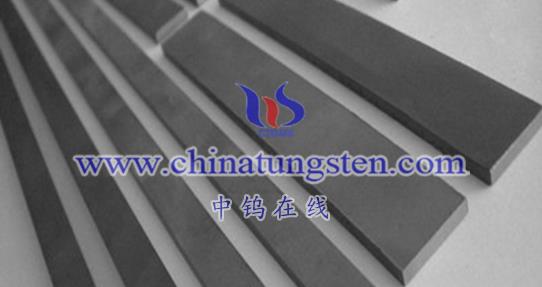

The possible applications of 90WMoNiFe alloy in the China Fusion Engineering Test Reactor (CFETR) are mainly reflected in the following aspects:

divertor material

Since 90WMoNiFe alloy has excellent high-temperature corrosion resistance and good thermal conductivity, it may be used as a divertor material in CFETR. The divertor is a very critical component in the fusion reactor. It is mainly used to remove impurities in the plasma and withstand the bombardment of the particle flow. This alloy can effectively withstand high temperatures and strong radiation environments, ensuring long-term stable operation of the divertor.

Structural materials

The high strength and good creep resistance of 90WMoNiFe alloy make it a potential structural material in CFETR. Structural materials in fusion reactors need to withstand extreme thermal loads and mechanical stresses, and this alloy can meet these requirements to ensure the stability and safety of the reactor structure.

heat sink material

In fusion reactions, large amounts of heat need to be efficiently dissipated to prevent equipment from overheating. The high thermal conductivity of 90WMoNiFe alloy makes it possible to become an ideal heat sink material for quickly transferring the heat generated by fusion to the cooling system to ensure the cooling efficiency of the reactor.

Neutron shielding materials

Fusion reactions produce large amounts of neutrons, which have a destructive effect on the structure and materials of the reactor. Due to its high density and good neutron absorption capabilities, 90WMoNiFe alloy may be used as a neutron shielding material to reduce neutron radiation damage to other parts of the reactor.

It should be noted that although 90WMoNiFe alloy has potential application value in CFETR, its long-term performance and stability in the fusion environment still require further research and verification. In addition, as fusion technology continues to develop, new materials and design solutions may continue to emerge, so it is necessary to consider multiple factors to select appropriate materials in practical applications.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595