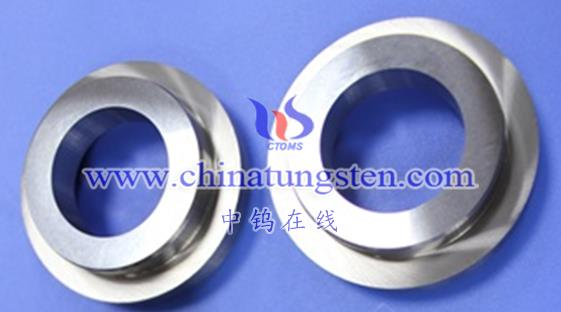

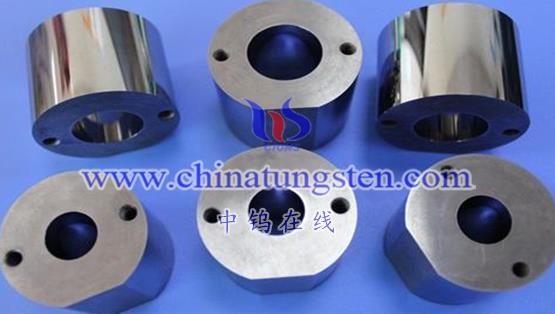

Tungsten-molybdenum-nickel-iron alloy has excellent corrosion resistance. This alloy contains high-melting-point metal elements such as tungsten and molybdenum, which gives it excellent high-temperature stability and oxidation resistance. At the same time, the addition of nickel and iron also enhances the corrosion resistance of the alloy. Therefore, tungsten-molybdenum-nickel-iron alloy can show good corrosion resistance in various harsh corrosive environments.

Specifically, tungsten-molybdenum-nickel-iron alloy can resist erosion by corrosive media such as strong acids, strong alkalis, and salt solutions, and can maintain stable performance even under high temperature and high pressure conditions. This makes the alloy widely used in chemical industry, petroleum, marine engineering and other fields. In these fields, equipment often needs to withstand harsh conditions such as corrosive media and high temperature and pressure. The abrasion resistance of tungsten-molybdenum-nickel-iron alloy can ensure long-term stable operation of equipment, reduce the frequency of maintenance and replacement, and reduce production costs.

In addition, tungsten-molybdenum-nickel-iron alloy also has excellent mechanical properties, such as high strength, high hardness and good wear resistance, which further enhance its wear resistance. Therefore, tungsten-molybdenum-nickel-iron alloy is an excellent corrosion-resistant material and has broad application prospects in chemical industry, petroleum, marine engineering and other fields.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595