Tungsten-molybdenum-nickel-iron alloy is widely used in the petrochemical industry, mainly due to its excellent corrosion resistance and high temperature stability. The following are some specific application cases:

Refining equipment

In the petroleum refining process, various equipment need to withstand high temperature, high pressure and corrosive media. Tungsten-molybdenum-nickel-iron alloy is often used to manufacture key components of oil refining equipment, such as reactors, cracking furnaces, heaters, etc., due to its excellent corrosion resistance and high temperature stability.

Catalytic cracking unit

Catalytic cracking is an important process in petrochemical industry, involving high temperature, high pressure and corrosive media. Tungsten-molybdenum-nickel-iron alloy is suitable for manufacturing reactors, regenerators, catalyst carriers and other components in catalytic cracking units due to its good corrosion resistance and high temperature stability.

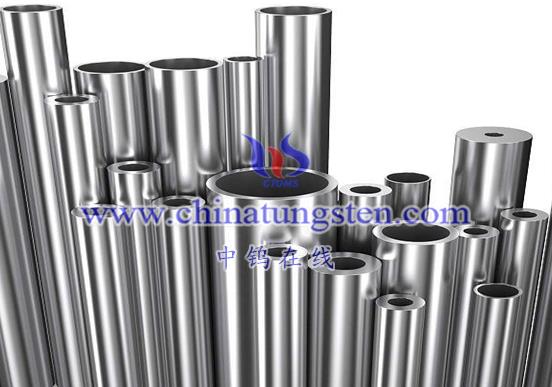

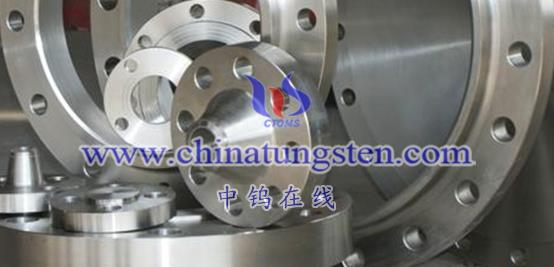

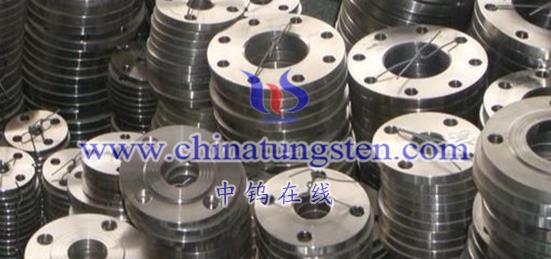

Pipelines and conveyor systems

Fluid transportation in the petrochemical industry requires a large number of pipelines and transportation systems. Tungsten-molybdenum-nickel-iron alloy is often used to manufacture key components of these pipelines and transportation systems, such as elbows, flanges, valves, etc., due to its excellent corrosion resistance and wear resistance.

Hydrotreating unit

In the petrochemical industry, hydrotreating is an important reaction process used to improve the quality and yield of oil products. Tungsten-molybdenum-nickel-iron alloy is suitable for manufacturing reactors, heaters and other components in hydrotreating equipment due to its good corrosion resistance and high temperature stability.

Corrosion Resistant Tanks and Containers

The petrochemical industry requires the storage of large quantities of chemicals and raw materials, which are often corrosive. Tungsten-molybdenum-nickel-iron alloy is often used to manufacture corrosion-resistant storage tanks and containers due to its excellent corrosion resistance to ensure the safety and stability of the storage process.

In short, tungsten-molybdenum-nickel-iron alloy has a wide range of application cases in the petrochemical industry, mainly involving the manufacturing of key components such as refining equipment, catalytic cracking units, pipelines and transportation systems, hydrotreating units, and corrosion-resistant storage tanks and containers. Its excellent corrosion resistance and high temperature stability enable these equipment to operate stably for a long time in harsh working environments, providing reliable guarantee for petrochemical production.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595