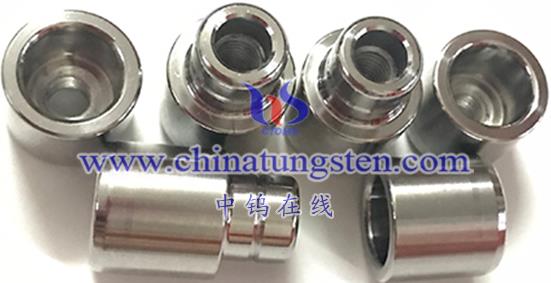

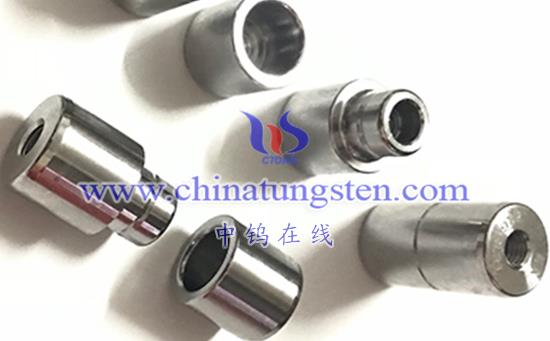

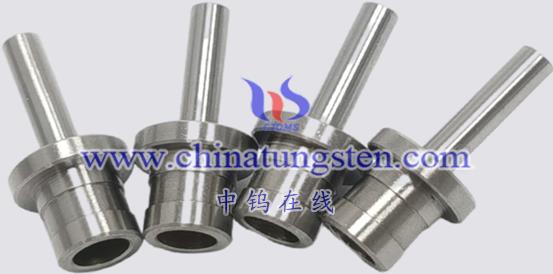

Application scenarios of 90 WMoNiFe alloy cooling inserts

Die-casting molds:

Automotive manufacturing: die-casting molds for key components such as automobile engines and transmissions.

Aerospace: high-performance die-casting molds for aerospace devices such as aircraft engines and rockets.

Hot forging molds:

Heavy machinery: hot forging molds for key components such as excavators and loaders.

Petrochemical: hot forging molds for petrochemical equipment under high temperature and high pressure.

Heat treatment equipment:

Metal processing

Used in the heat treatment process of metal materials, such as quenching and tempering.

Electronic industry

Heat treatment equipment for the manufacture of electronic components such as semiconductors and integrated circuits.

Advantages of 90 WMoNiFe alloy cooling inserts

High temperature stability:

In high temperature working environments, 90 WMoNiFe alloy cooling inserts can maintain their hardness and strength, are not prone to softening or deformation, and ensure the accuracy and stability of the mold. Compared with traditional materials, this alloy has higher thermal stability and thermal fatigue resistance, and is suitable for working environments with long-term high temperature operation.

Excellent thermal conductivity:

90 WMoNiFe alloy has good thermal conductivity and can quickly transfer the heat inside the mold to the coolant to achieve rapid cooling. This helps to improve the production efficiency of the mold, reduce mold damage and deformation caused by thermal stress, and extend the service life of the mold.

High wear resistance:

The high hardness and wear resistance of the alloy make the cooling inserts less prone to wear during long-term use, maintaining the precision and surface quality of the mold.

Compared with traditional materials, 90 WMoNiFe alloy cooling inserts have higher wear resistance, which can significantly reduce the maintenance and replacement frequency of the mold and reduce production costs.

Good processability:

Although 90 WMoNiFe alloy has a high hardness, it can be processed into complex shapes and structures through proper process control, such as heat treatment, cutting, etc.

This provides greater flexibility in the design and manufacture of molds, allowing 90 WMoNiFe alloy cooling inserts to adapt to various complex mold structure requirements.

Corrosion resistance:

In certain specific chemical environments or high-temperature oxidizing atmospheres, 90 WMoNiFe alloys exhibit good corrosion resistance.

This enables the alloy to maintain stable performance in harsh working environments, reducing mold damage and maintenance costs caused by corrosion.

90 WMoNiFe alloy cooling inserts have broad application prospects in the mold industry due to their high temperature stability, excellent thermal conductivity, high wear resistance, good processability and corrosion resistance. Especially in working environments that need to withstand high temperatures, high pressures and heavy loads, the application advantages of this alloy are more obvious, which can significantly improve the service life and production efficiency of the mold.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595