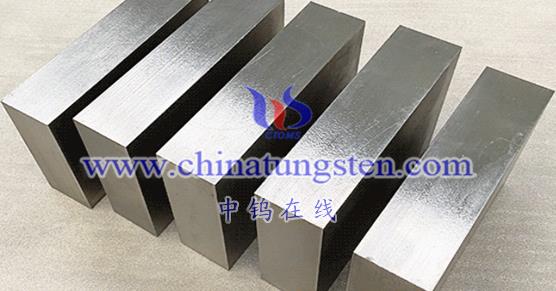

90 WMoNiFe alloy wear-resistant insert is a high-performance material widely used in the industrial field, especially suitable for occasions that need to withstand high temperature, high pressure and high wear environment. This alloy combines the advantages of metal elements such as tungsten, molybdenum, nickel and iron. Through precise alloy design and advanced manufacturing technology, it forms an alloy material with excellent wear resistance, high temperature stability and good mechanical properties.

- The concept of 90 WMoNiFe alloy wear-resistant insert

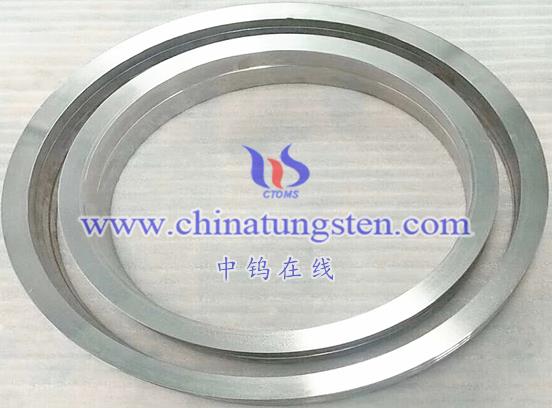

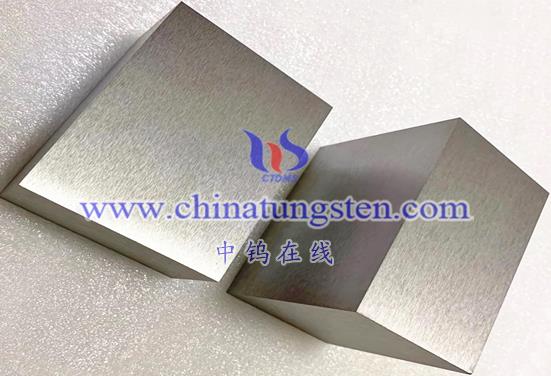

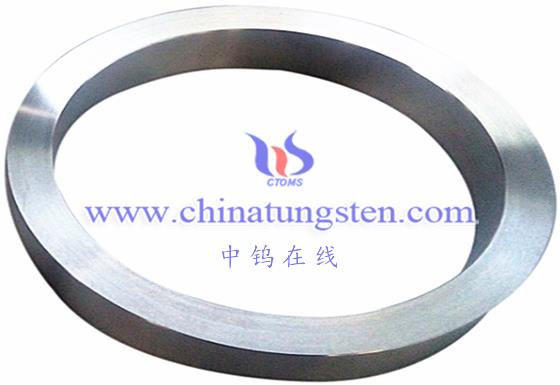

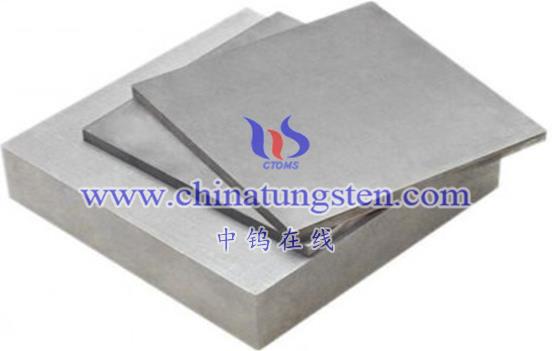

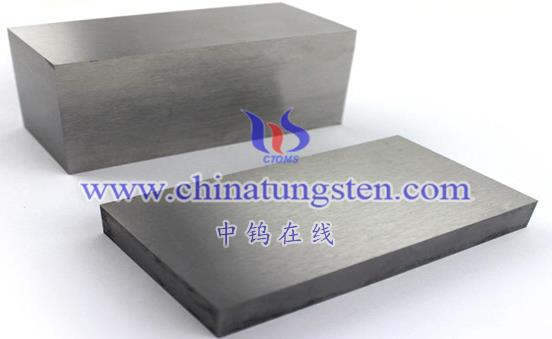

90 WMoNiFe alloy wear-resistant insert is an alloy material composed of metal elements such as tungsten, molybdenum, nickel and iron. It is prepared into inserts suitable for wear-resistant applications through specific alloy ratios and process control. These inserts are usually embedded in various equipment and tools, such as molds, mechanical parts, etc., to improve their wear resistance and service life.

- Characteristics of 90 WMoNiFe alloy wear-resistant insert

High wear resistance

90 WMoNiFe alloy has excellent wear resistance, can maintain a stable wear rate for a long time in harsh working environments, and extend the service life of equipment and tools.

High temperature stability

The alloy can maintain its mechanical properties and chemical stability under high temperature conditions, is not prone to softening or oxidation, and is suitable for high temperature working environments.

Good mechanical properties

90 WMoNiFe alloy has high strength, high hardness and good toughness, can withstand high pressure and heavy load impact, and maintain the stability and precision of equipment and tools.

Excellent thermal conductivity

The alloy has good thermal conductivity and can effectively conduct heat away from the friction part, reduce the working temperature and reduce thermal stress.

Good processability and weldability

90 WMoNiFe alloy can be formed and connected through conventional processing and welding processes, which is convenient for manufacturing and maintenance.

- Advantages of 90 WMoNiFe alloy wear-resistant inserts

Improve equipment performance

The use of 90 WMoNiFe alloy wear-resistant inserts can significantly improve the performance and reliability of equipment and tools, reduce failure rate and maintenance costs.

Extend service life

The wear resistance and high temperature stability of the alloy enable equipment and tools to operate stably for a long time in harsh working environments, extending service life.

Improve production efficiency

The use of 90 WMoNiFe alloy wear-resistant inserts can improve production efficiency and reduce production costs due to the reduction in the number of repairs and replacements.

Wide range of applications

This alloy is suitable for a variety of industries and fields, such as automobile manufacturing, aerospace, petrochemical, metallurgical industry, etc., and has broad application prospects.

- Application scenarios of 90 WMoNiFe alloy wear-resistant inserts

Mold manufacturing

90 WMoNiFe alloy wear-resistant inserts are widely used in the manufacture of various molds, such as die-casting molds, hot forging molds, injection molds, etc. These molds need to withstand high temperature, high pressure and high wear working conditions, and the excellent performance of this alloy can meet these requirements and improve the service life and production efficiency of the mold.

Mechanical parts

In mechanical equipment, some key components such as bearings, gears, sliders, etc. need to withstand high wear and high temperature working environments. The application of 90 WMoNiFe alloy wear-resistant inserts can significantly improve the wear resistance and service life of these components, ensuring the stable operation of mechanical equipment.

Aerospace field

In the field of aerospace, some key components need to withstand high temperature, high pressure and high wear working environments, such as engine components, gas turbines, etc. The application of 90 WMoNiFe alloy wear-resistant inserts can improve the high temperature resistance and wear resistance of these components, ensuring their long-term stable operation.

Petrochemical industry

In the field of petrochemical industry, some equipment and pipelines need to withstand high temperature, high pressure and corrosive media working environment. The application of 90 WMoNiFe alloy wear-resistant inserts can improve the wear resistance and corrosion resistance of these equipment and pipelines, extend service life and reduce the risk of leakage.

- Professional terms and data of 90 WMoNiFe alloy wear-resistant inserts

Chemical composition

The chemical composition of 90 WMoNiFe alloy plays a decisive role in its performance. The common composition range is: W 20-30%, Mo 20-30%, Ni 20-30%, Fe balance. The specific composition ratio will be adjusted according to the specific application requirements.

Physical properties

The physical properties of the alloy include density, thermal expansion coefficient, thermal conductivity, etc. For example, the density is usually between 10-12 g/cm³, the thermal expansion coefficient is low, and the thermal conductivity is high. These characteristics contribute to good thermal stability and wear resistance.

Mechanical properties

The mechanical properties of 90 WMoNiFe alloy include tensile strength, yield strength, elongation, impact toughness, etc. These performance indicators are crucial to evaluate the performance of the alloy in a specific working environment.

Wear resistance test

In order to evaluate the wear resistance of the alloy, wear tests such as sliding wear test and impact wear test are usually carried out. These tests can simulate the wear conditions in the actual working environment, so as to obtain the wear resistance data of the alloy.

High temperature performance test

For the high temperature stability of 90 WMoNiFe alloy, high temperature tensile test and high temperature creep test are carried out. These tests can evaluate the mechanical properties and stability of the alloy under high temperature conditions.

Microstructure analysis

The microstructure of the alloy can be observed by scanning electron microscopy (SEM), transmission electron microscopy (TEM) and other means, and the influence of factors such as grain size, phase composition and interface structure on the performance can be analyzed.

Application field data

In the application of different industries, the service life, maintenance frequency, production efficiency and other key indicators of 90 WMoNiFe alloy wear-resistant inserts will be recorded and analyzed in detail. These data provide a strong basis for evaluating the performance of the alloy in actual applications.

- Manufacturing process of 90 WMoNiFe alloy wear-resistant inserts

Raw material preparation

Select high-quality tungsten, molybdenum, nickel, iron and other metal raw materials, and mix and pre-treat them according to the predetermined composition ratio.

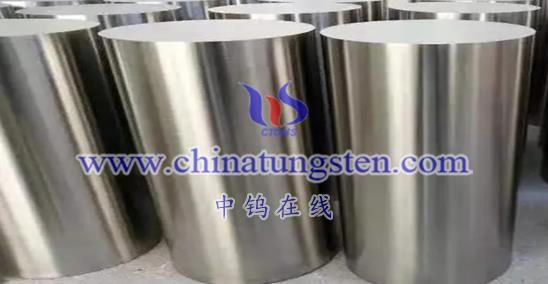

Sintering, smelting and casting

The mixed raw materials are sintered or smelted, and the alloy composition is ensured to be uniform by controlling the sintering and smelting temperature and smelting time. Then the molten alloy is poured into a mold for casting to form the required shape and size. Or the sintered blank is refined to meet the product requirements.

Heat treatment

The cast alloy is heat treated, and the grain structure and phase composition of the alloy are adjusted through heating, insulation and cooling processes to improve its mechanical properties and wear resistance.

Machining

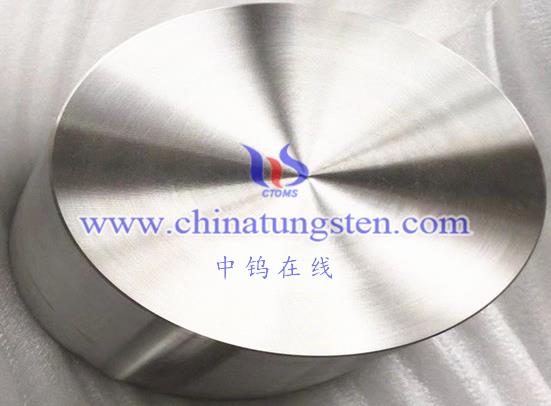

The heat-treated alloy is mechanically processed, such as turning, milling, drilling, etc., to obtain precise size and shape.

Surface treatment

According to needs, the alloy surface is polished, sprayed, etc. to improve its wear resistance and corrosion resistance.

VII. Development trend of 90 WMoNiFe alloy wear-resistant inserts

With the continuous advancement of science and technology and the rapid development of the industrial field, 90 WMoNiFe alloy wear-resistant inserts will continue to develop towards higher performance, wider application and more environmentally friendly manufacturing. In the future, people may further improve the wear resistance, high temperature resistance and mechanical properties of 90 WMoNiFe alloy wear-resistant inserts by optimizing alloy composition, improving manufacturing processes, and developing new wear-resistant materials. At the same time, as the concept of sustainable development is deeply rooted in people’s hearts, the research and development of environmentally friendly 90 WMoNiFe alloy wear-resistant inserts will also become an important direction in the future.

As a high-performance wear-resistant material, 90 WMoNiFe alloy wear-resistant inserts have broad application prospects in the industrial field. Through in-depth research and continuous innovation, people will be able to develop more excellent and more environmentally friendly 90 WMoNiFe alloy wear-resistant inserts, and make greater contributions to the sustainable development of the industrial field. For more information on 90 WMoNiFe alloy wear-resistant inserts, more detailed and in-depth product and material performance, please contact the professional knowledge of CTIA GROUP LTD.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595