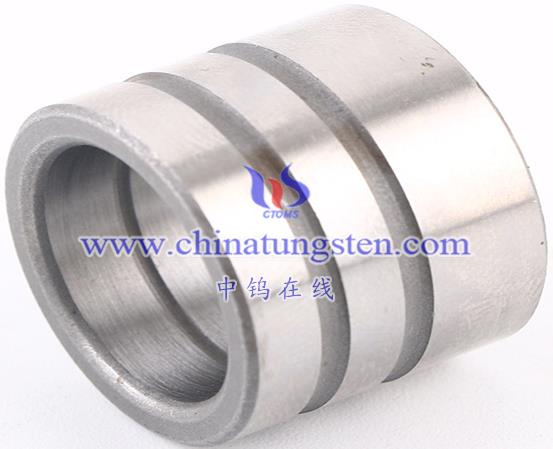

90 WMoNiFe alloy gate bushing is most suitable for use in the following environments:

high temperature environment

Because 90 WMoNiFe alloy has excellent high-temperature stability, the gate bushing can maintain the stability of its structure and performance under sustained high-temperature operating conditions. In injection molding, die-casting and other molding processes, the temperature of the molten material is often high, and the 90 WMoNiFe alloy gate bushing can withstand such high-temperature impact to ensure the smooth progress of the molding process.

high pressure environment

During the molding process, molten material creates high pressure as it passes through the gate bushing. The high strength and excellent mechanical properties of 90 WMoNiFe alloy enable it to withstand such high pressure, ensuring that the gate bushing will not be deformed or damaged in a high-pressure environment.

High wear environment

The flow and impact of molten material in the gate bushing can cause wear. The high hardness and wear resistance of 90 WMoNiFe alloy enable it to resist this wear and extend the service life of the gate bushing. Especially when the gate bushing needs to be replaced frequently, the use of 90 WMoNiFe alloy material can significantly reduce the number of replacements and reduce production costs.

corrosive environment

Some molding materials can be corrosive and cause damage to the gate bushing material. 90 WMoNiFe alloy has good corrosion resistance and can resist the erosion of corrosive environments to a certain extent, ensuring the stability and reliability of the gate bushing.

Tungsten molybdenum nickel iron alloy gate bushing is most suitable for use in high temperature, high pressure, high wear and corrosive environments. Under these harsh working conditions, 90 WMoNiFe alloy gate bushings can maintain their excellent performance, ensuring the smooth progress of the molding process and improving production efficiency and product quality. At the same time, it can also reduce production costs and maintenance costs, bringing greater economic benefits to enterprises.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595