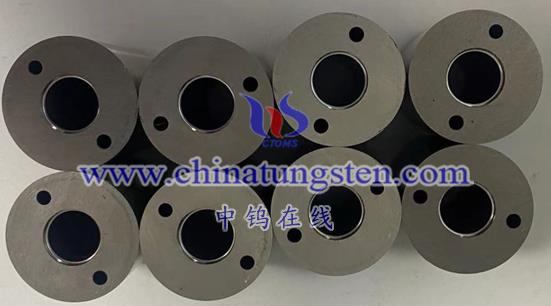

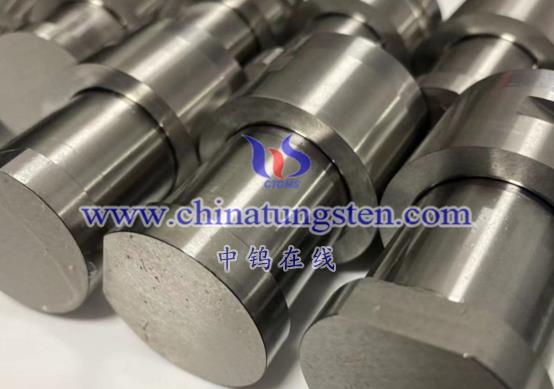

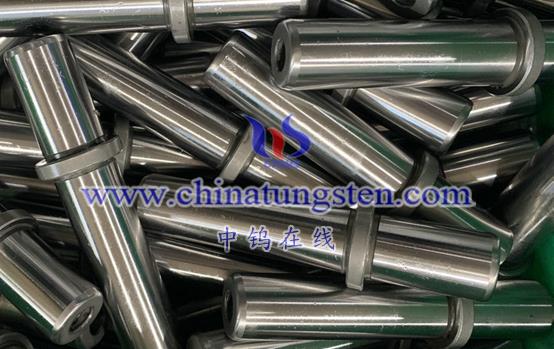

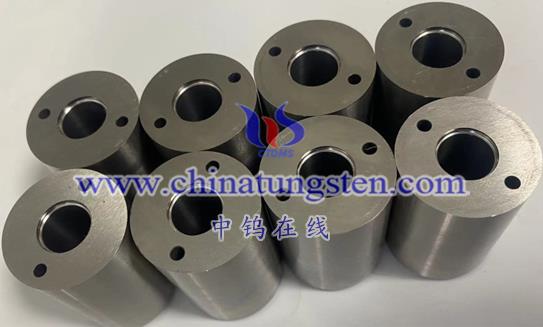

90 WMoNiFe alloy gate bushings have excellent high temperature stability, wear resistance, high strength and good thermal conductivity, so they have a wide range of application scenarios in multiple fields. The following are the main application scenarios of 90 WMoNiFe alloy gate bushings:

Injection molding process

In injection molding, molten plastic enters the mold cavity through the gate. 90 WMoNiFe alloy gate bushings can withstand high temperature and high pressure, ensure the uniform flow and precise injection of plastic, and improve product quality and production efficiency.

Die casting molding process

In the die casting process, molten metal enters the mold through the gate. 90 WMoNiFe alloy gate bushings can withstand the high temperature and high pressure of the metal, ensure the smooth flow and precise filling of the molten metal, and improve the density and dimensional accuracy of the die casting.

Continuous casting process

In continuous casting, molten metal flows into the crystallizer through the gate. 90 WMoNiFe alloy gate bushings can resist the scouring of high temperature and molten metal, keep the shape and size of the gate stable, and ensure the smooth progress of the continuous casting process.

Glass Fiber Reinforced Plastic (GFRP) Molding

During the GFRP molding process, the molten resin enters the mold through the gate and combines with the glass fiber. The 90 WMoNiFe alloy gate bushing can withstand high temperatures and resin scouring, ensuring the uniform flow of resin and the quality of GFRP products.

Other high-temperature, high-pressure, and high-wear environments

90 WMoNiFe alloy gate bushings are also suitable for other molding processes that need to withstand high temperatures, high pressures, and high wear, such as powder metallurgy, rubber molding, and other fields.

In short, the application scenarios of 90 WMoNiFe alloy gate bushings are mainly concentrated in high-temperature, high-pressure, and high-wear molding processes, which can improve production efficiency, product quality, and economic benefits.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595