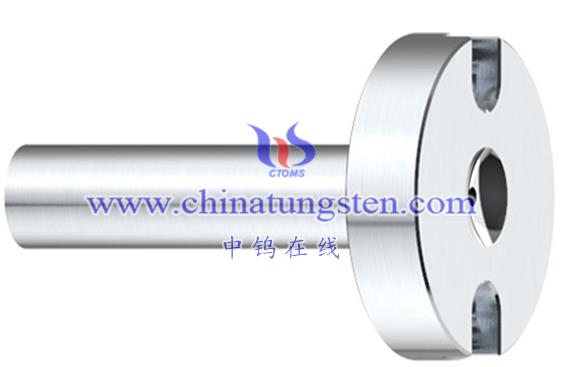

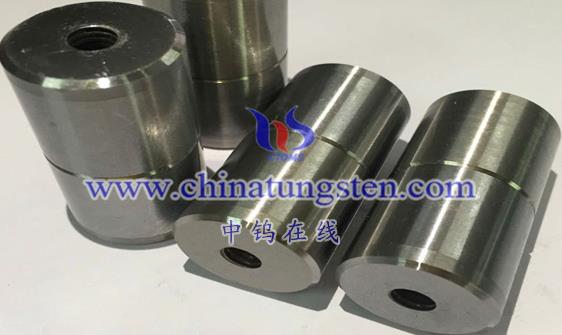

90 WMoNiFe alloy gate bushing plays a vital role in the molding process, and its role is mainly reflected in the following aspects:

High temperature stability and wear resistance

As a key component in the molding process, the gate bushing needs to withstand the high temperature impact and flow friction of the molten material. Due to its excellent high temperature stability and wear resistance, the 90 WMoNiFe alloy enables the gate bushing to maintain structural stability and good wear resistance in a long-term high temperature working environment, thereby extending its service life.

Accurately control the flow of molten materials

The design and manufacturing accuracy of the gate bushing directly affects the flow and distribution of the molten material in the mold. The high hardness and high-precision processing performance of 90 WMoNiFe alloy ensure that the gate bushing can accurately control the flow direction and speed of the molten material, achieve precise molding, and improve product quality.

Prevent molten material leakage

During the molding process, the molten material needs to enter the mold cavity through the gate. If the gate bushing is improperly designed or the material performance is poor, molten material leakage is likely to occur, affecting the appearance and quality of the product. The 90 WMoNiFe alloy gate bushing has good sealing performance, which can effectively prevent the leakage of molten materials and ensure the smooth progress of the molding process.

Improve production efficiency

Due to the excellent wear resistance and high temperature stability of the 90 WMoNiFe alloy gate bushing, the frequency of replacing the bushing can be reduced, the maintenance cost can be reduced, and the production efficiency can be improved. At the same time, its ability to accurately control the flow of molten materials also helps to reduce the defective rate and further improve production efficiency.

Adapt to a variety of molding processes and materials

The 90 WMoNiFe alloy gate bushing has a wide range of adaptability and can be used in a variety of molding processes and materials, such as injection molding, die casting, continuous casting, etc. This makes it have a wide range of application prospects in the field of molding technology.

In summary, the 90 WMoNiFe alloy gate bushing plays a role in high temperature stability, wear resistance, precise control of molten material flow, leakage prevention and improved production efficiency in the molding process, which is of great significance to improving product quality and production efficiency.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595