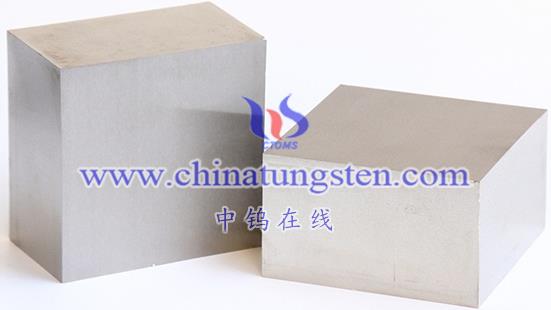

90WMoNiFe alloy block is an alloy material composed of tungsten as the base and adding a small amount of nickel, iron, molybdenum and other alloying elements. This alloy block has some significant performance characteristics, such as low expansion coefficient, high thermal conductivity and good red hardness, which make it widely used in many fields.

Specifically, 90WMoNiFe alloy blocks are often used to manufacture components that operate in high-temperature and high-stress environments due to their excellent thermal and mechanical properties. For example, in the field of die-casting molds, it can be used to make mold parts that can withstand high temperatures and maintain shape stability; in the field of hot-forged valves, it can be used as an anvil material to withstand extreme thermal loads.

In addition, 90WMoNiFe alloy blocks may also be used in other fields that require high strength, high hardness and good thermal stability, such as aerospace, energy, chemical industry, etc.

The shape, size and properties of 90WMoNiFe alloy blocks may be customized based on specific application needs. Therefore, the specific parameters and uses of alloy blocks may vary between manufacturers or application scenarios.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595