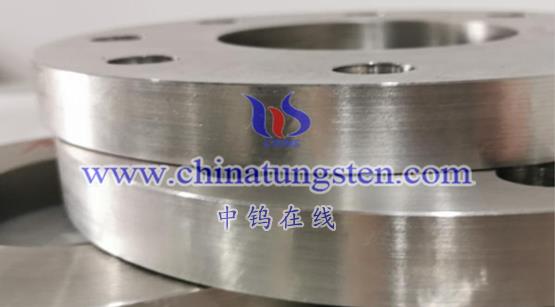

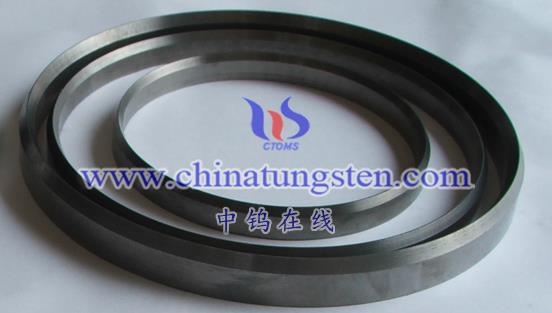

90WMoNiFe alloy sealing ring is a key component used to seal fluid media in harsh environments such as high temperature, high pressure and strong corrosion. This sealing ring is made of an alloy material composed of metal elements such as tungsten, molybdenum, nickel and iron. The selection of these elements makes the alloy have excellent high temperature resistance, high pressure resistance and corrosion resistance.

Tungsten and molybdenum have high melting points, so the alloy can maintain stable performance at high temperatures. The addition of nickel enhances the corrosion resistance of the alloy, while iron improves the mechanical strength of the alloy. The combined effect of these elements enables the 90WMoNiFe alloy sealing ring to maintain excellent sealing effect under extreme working conditions.

The design of the 90WMoNiFe alloy sealing ring also takes into account fluid dynamics and sealing mechanisms to ensure reliable sealing under various working conditions. Its precise manufacturing process and high-quality material selection also ensure the long-term stability and durability of the sealing ring.

90WMoNiFe alloy sealing ring is a high-performance and high-reliability sealing element, which is widely used in the fields of petroleum, chemical industry, electric power, aerospace, etc. where high temperature, high pressure and strong corrosive environment sealing are required

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595