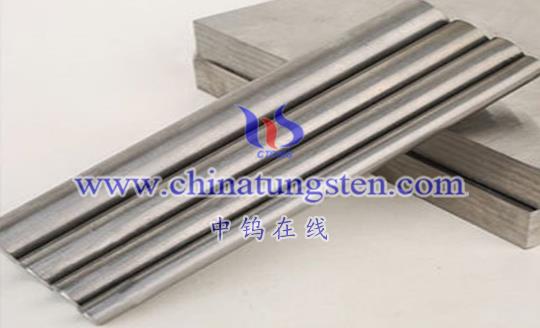

90WMoNiFe alloy has excellent wear resistance and corrosion resistance.

In terms of wear resistance, the high hardness and good mechanical properties of 90WMoNiFe alloy make it an ideal material for manufacturing wear-resistant parts. The hardness of this alloy is usually very high, and it can reach a certain Rockwell hardness value, which enables it to maintain stable performance for a long time in a friction and wear environment. Therefore, 90WMoNiFe alloy is widely used in industrial fields such as manufacturing tools, bearings and parts that require wear resistance and corrosion resistance.

In terms of corrosion resistance, 90WMoNiFe alloy also performs well. It can resist erosion by a variety of corrosive media, including strong acids, strong alkalis and salts. The corrosion resistance of this alloy is mainly due to its elemental composition and microstructure, which enables it to maintain stability and reliability for a long time in harsh environments.

In summary, 90WMoNiFe alloy has excellent wear resistance and corrosion resistance, and can meet the high requirements of material performance in various industrial fields. However, the specific wear and corrosion resistance may vary depending on factors such as the composition of the alloy, the manufacturing process and the use environment. Therefore, when selecting and using 90WMoNiFe alloy, it is necessary to evaluate and select according to the specific application requirements and conditions.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595