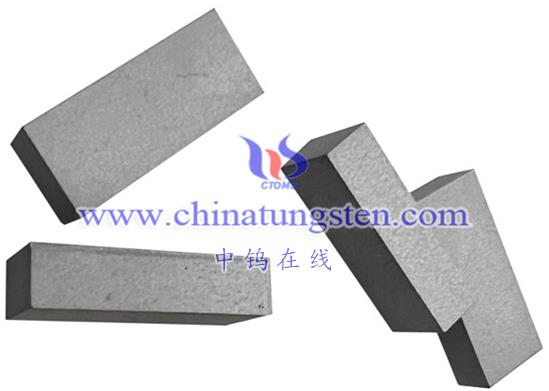

Tungsten-molybdenum alloy is an alloy material composed of tungsten (W) and molybdenum (Mo) elements. Its unique physical and chemical properties make it widely used in multiple industrial fields. The following will give an in-depth introduction to tungsten-molybdenum alloys from various aspects such as alloy composition, properties, preparation processes, and application fields, and use professional terminology and professional data to elaborate.

Tungsten-molybdenum alloy composition

The composition ratio of tungsten-molybdenum alloy can be adjusted according to specific application requirements. Generally speaking, the tungsten content in commonly used tungsten-molybdenum alloys is usually between 30% and 50% (mass percentage). Adjustment of this ratio can significantly affect the physical and chemical properties of the alloy, such as melting point, hardness, strength, etc.

Properties of tungsten-molybdenum alloy

Melting point: The melting point of tungsten-molybdenum alloy increases with the increase of tungsten content. Specifically, when the tungsten content is increased to a certain level, the melting point of the alloy will be hundreds of degrees Celsius higher than that of pure molybdenum. This characteristic makes tungsten-molybdenum alloys have excellent stability in high-temperature environments.

Hardness and strength of tungsten-molybdenum alloy

The hardness and strength of tungsten-molybdenum alloy also increase with the increase of tungsten content. This excellent mechanical property allows tungsten-molybdenum alloys to maintain structural stability and integrity under high loads and extreme working conditions.

Corrosion resistance of tungsten-molybdenum alloy

Tungsten-molybdenum alloys have good corrosion resistance to most organic and inorganic acids, bases and salts. This enables it to be used stably for a long time in harsh environments and is not easily corroded.

Thermal conductivity of tungsten-molybdenum alloy

Tungsten-molybdenum alloy has high thermal conductivity, which makes it of great application value in the manufacture of high-temperature heat transfer components.

Electron emission characteristics of tungsten-molybdenum alloy

Tungsten-molybdenum alloy also has good electron emission properties, which makes it occupy an important position in the manufacturing of high-performance materials such as electronic devices and electrodes.

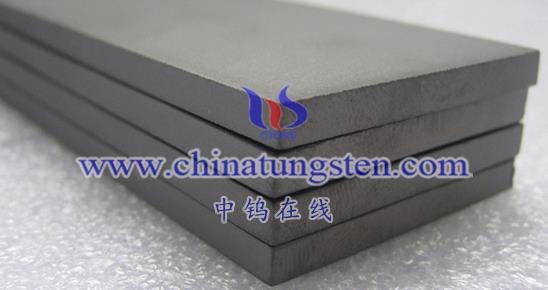

Preparation process of tungsten-molybdenum alloy

The preparation process of tungsten-molybdenum alloy mainly includes two methods: powder metallurgy sintering post-processing and smelting processing.

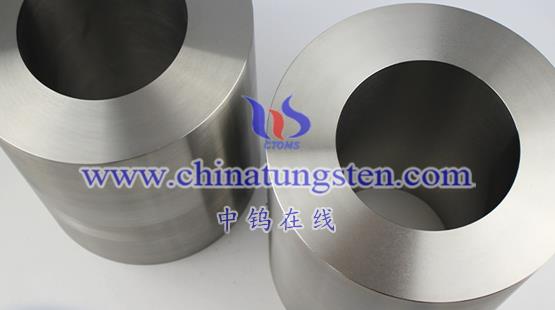

Processing after powder metallurgy sintering

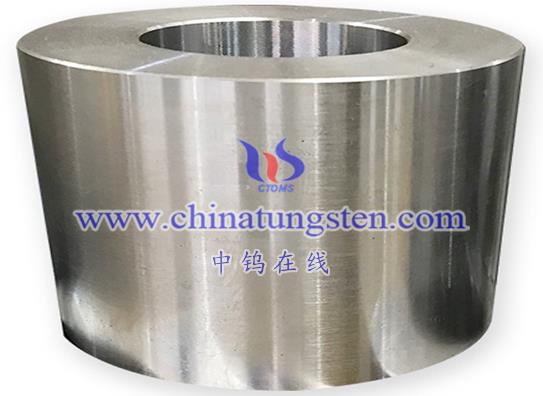

In this method, tungsten and molybdenum powders are first mixed evenly in a certain proportion, and then alloy materials of the required shape are made through pressing, sintering and other processes. This method can produce tungsten-molybdenum alloy parts with complex shapes and structures.

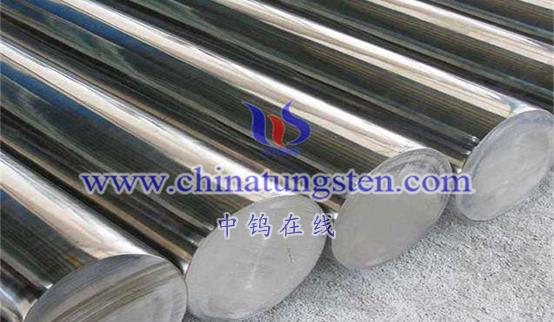

Smelting processing

This method is to put the raw materials of tungsten and molybdenum into a smelting furnace for smelting, and then make alloy materials through casting, rolling and other processes. This method is suitable for preparing large quantities of tungsten-molybdenum alloy materials.

Application fields of tungsten-molybdenum alloy

Tungsten-molybdenum alloy is widely used in many fields due to its excellent properties, including but not limited to the following aspects:

Aerospace field

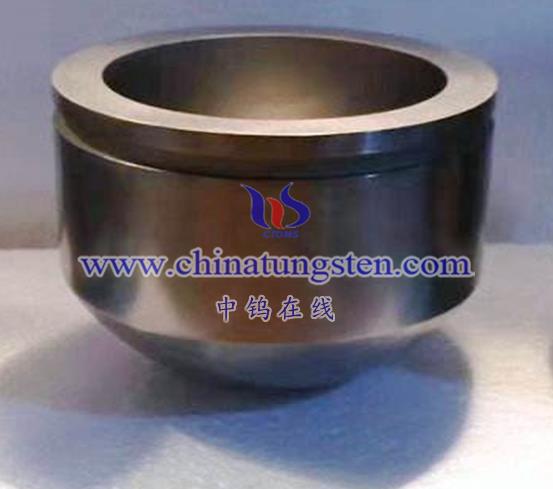

The high melting point, high strength and heat resistance of tungsten-molybdenum alloys make them ideal for aerospace components. For example, it can be used to manufacture high-temperature parts of aircraft engines, rocket nozzles, etc.

Nuclear industry

Because tungsten-molybdenum alloy has good radiation resistance and corrosion resistance, it is often used in high-temperature components in nuclear reactors, such as reactor core structures, spent fuel cladding materials, etc.

Electronic industry field

The high thermal conductivity and electron emission properties of tungsten-molybdenum alloys make them important in the manufacture of electronic devices. For example, it can be used to make high-temperature electron tubes, vacuum circuit breaker contacts, etc.

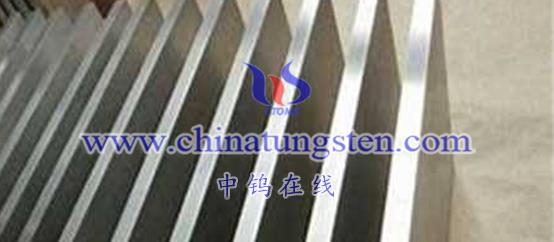

Tool manufacturing field

The hardness and wear resistance of tungsten-molybdenum alloy make it an ideal material for manufacturing high-speed cutting tools, wear-resistant cutting tools, etc.

In summary, tungsten-molybdenum alloy is a metal material with excellent performance and application prospects. Through an in-depth understanding of its composition, properties, preparation processes and application fields, we can better utilize this material and provide strong support for the development of various fields. At the same time, with the continuous advancement of science and technology and the continuous expansion of applications, it is believed that tungsten-molybdenum alloys will have broader application space and development prospects in the future.

More details of tungsten alloy product, please visit website: http://tungsten-alloy.com/

Please contact CHINATUNGSTEN for inquiry and order of tungsten alloy:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595