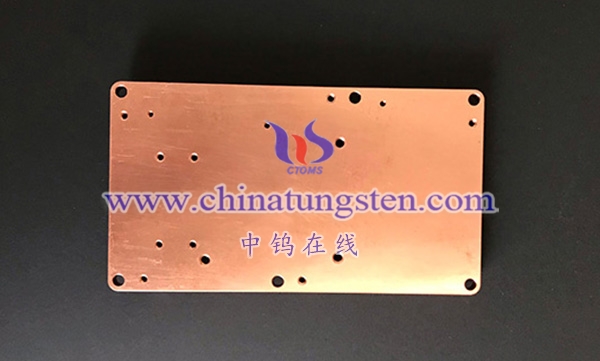

1. Powder metallurgy process

The manufacture of CuW base plates mainly adopts powder metallurgy process. First, tungsten powder and copper powder are mixed evenly in a certain proportion, and then the mixed powder is made into CuW base plates of the required shape through process steps such as pressing and sintering. This manufacturing process has the advantages of high flexibility and high production efficiency, and can produce CuW base plates of various shapes and sizes.

2. Casting process

In addition to powder metallurgy process, CuW base plates can also be manufactured by casting process. The casting process is to melt the alloy of tungsten and copper, pour it into a mold, cool and solidify it, and obtain a CuW base plate of the required shape. This manufacturing process is suitable for the production of large and complex CuW base plates.

More details of Tungsten Copper Heat Sinks, please visit website: http://tungsten-copper.com/Tungsten-Copper-Heat-Sink.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595