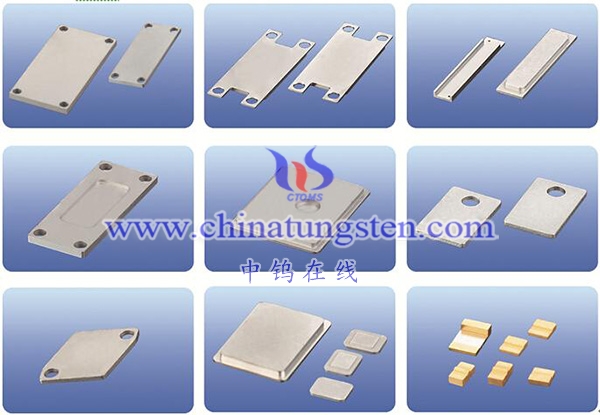

1. Improvement of material performance

With the continuous development of science and technology, the requirements for the performance of CuW base plate are getting higher and higher. In the future, the thermal conductivity, electrical conductivity, strength and toughness of CuW base plate can be further improved by improving the manufacturing process and optimizing the material ratio to meet the packaging and heat dissipation requirements of electronic components with higher performance requirements.

2. Research and development of new composite materials

In addition to tungsten copper composite materials, other new composite materials can be developed as packaging materials in the future, such as tungsten silver composite materials, tungsten nickel composite materials, etc. These new composite materials may have higher thermal conductivity, better corrosion resistance and higher operating temperature, providing more options for electronic component packaging and heat dissipation.

3. Green and environmental protection development

With the continuous improvement of environmental awareness, the development of CuW base plate in the future also needs to pay more attention to environmental protection and sustainability. Environmental pollution and resource consumption in the production process of CuW base plate can be reduced by adopting environmentally friendly raw materials, optimizing production processes, and improving resource utilization, so as to promote green and environmental protection development.

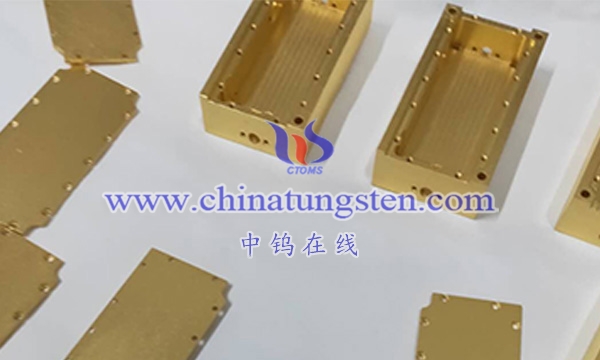

4. Expanding application areas

At present, CuW base plate are mainly used in the fields of electronic component packaging and heat dissipation. In the future, with the continuous development of science and technology and the continuous growth of application demand, the application field of CuW base plate will be further expanded. For example, in the fields of new energy vehicles and renewable energy, CuW base plate may play an important role.

In short, as an excellent thermal conductivity material, CuW base plate have broad application prospects in the heat dissipation and packaging of electronic equipment. With the continuous development of science and technology and the continuous growth of application demand, the performance of CuW base plate will continue to improve, and the application field will continue to expand.

More details of Tungsten Copper Heat Sinks, please visit website: http://tungsten-copper.com/Tungsten-Copper-Heat-Sink.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595