Generally speaking, the production process of molybdenum includes the following steps:

Molybdenum ore beneficiation: Molybdenum usually exists in molybdenum ore in the form of sulfide, so molybdenum ore needs to be beneficiated to separate molybdenum ore.

Molybdenum ore leaching: After molybdenum ore is crushed, ground, soaked, etc., the molybdenum can be extracted to form a molybdenum leaching solution.

Purification of molybdenum leaching solution: The molybdenum leaching solution also contains other impurities, such as copper and iron, which need to be purified to increase the concentration of molybdenum in the molybdenum leaching solution.

Reduction of molybdenum leaching solution: Molybdenum ions in molybdenum leaching solution are reduced to molybdenum powder, which can be reduced by reducing agents such as hydrogen or sodium sulfite.

Smelting of molybdenum powder: The reduced molybdenum powder is smelted to remove impurities, and at the same time adjust the composition and purity of molybdenum to form a high-purity molybdenum billet.

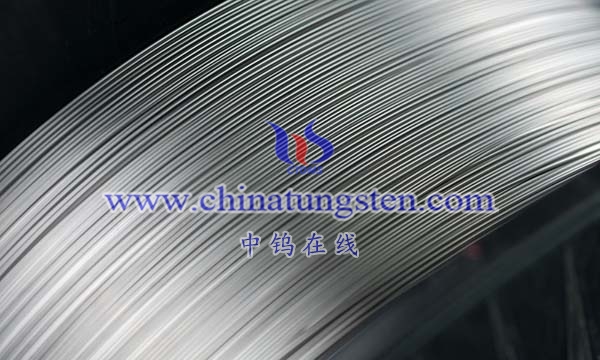

Processing of molybdenum blanks and product manufacturing: After processing tungsten blanks, various molybdenum products can be produced, such as molybdenum plates, molybdenum rods, molybdenum wires, etc., to meet the needs of different fields.

It should be noted that the production process of molybdenum may vary due to the source of molybdenum ore and different extraction techniques, but generally the above steps are relatively common.

More details of molybdenum or molybdenum products, please visit website: http://molybdenum.com.cn/

Please contact CHINATUNGSTEN for inquiry and order of molybdenum products:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595