The preparation process of the diffused barium tungsten cathode usually includes the following steps:

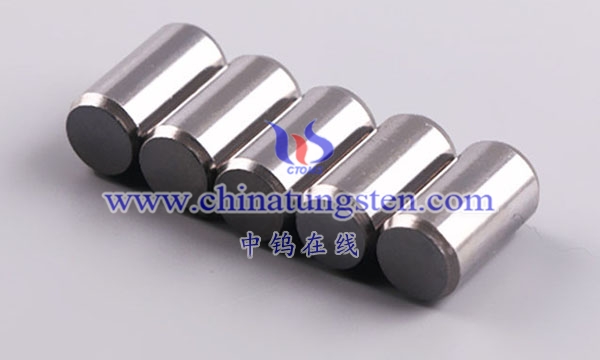

- Preparation of tungsten matrix

Raw material preparation

Select high-purity tungsten powder or other suitable raw materials.

Molding

Press or inject the tungsten powder into the shape of a porous tungsten matrix. This is usually achieved through powder metallurgy technology, such as pressing molding, injection molding, etc.

Sintering

The formed tungsten matrix is sintered at high temperature to give it sufficient strength and pore structure.

- Barium salt impregnation

Prepare impregnation solution

Mix barium salt (such as BaO, BaCO₃, etc.) with an appropriate amount of flux (such as Al₂O₃, CaO, etc.), and add organic solvent (such as ethanol) to make an impregnation solution.

Impregnation treatment

Immerse the porous tungsten matrix in the impregnation solution so that the barium salt fully penetrates into the pores of the matrix.

Drying

The impregnated tungsten matrix is dried to remove the organic solvent.

- Activation treatment

High temperature treatment

The impregnated and dried tungsten substrate is heated at a high temperature (such as 1000-1200°C) to make the barium salt react with the tungsten substrate to generate active barium atoms.

Vacuum treatment

During the activation process, it is usually necessary to maintain a vacuum environment to avoid contamination of the cathode by impurity gases.

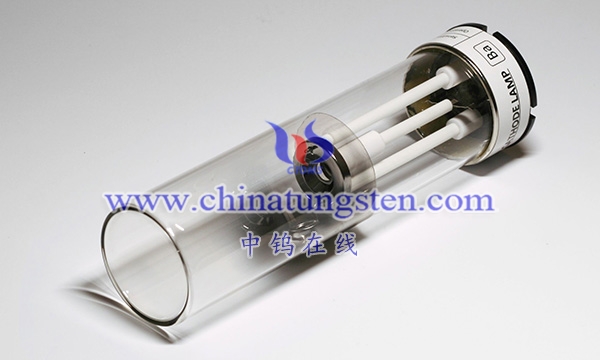

- Packaging and testing

Packaging

The activated diffused barium tungsten cathode is packaged to protect it from the external environment.

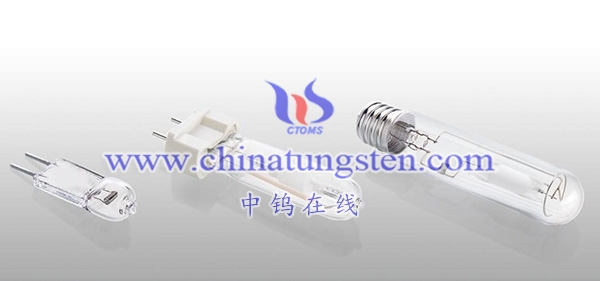

Testing

The packaged cathode is tested for emission performance, including the evaluation of emission current density, emission stability and other indicators.

The preparation process of the diffused barium tungsten cathode may vary depending on the specific application requirements and equipment conditions. In the actual preparation process, it is necessary to adjust and optimize according to the specific situation. At the same time, in order to obtain a longer cathode life and better emission performance, the preparation process needs to be continuously improved and innovated.

More details of tungsten barium electrode or tungsten barium cathode, please visit website: http://tungsten.com.cn/barium-tungsten-cathode.html

Please contact CHINATUNGSTEN ONLINE for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595