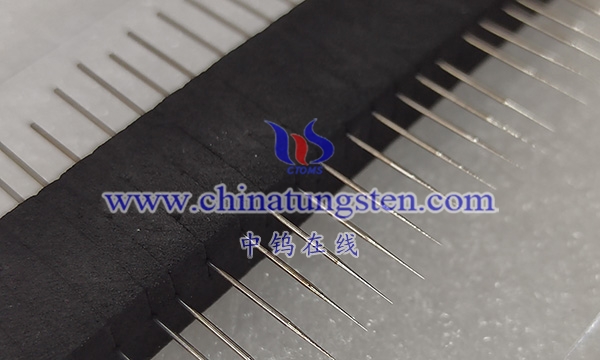

As an important metal material, tungsten ejecting needles have a series of unique performance characteristics. The following is a detailed introduction to the main performance characteristics of tungsten ejecting needles and their related data:

1. High density: Tungsten ejecting needles have a high density, usually 19.3g/cm³, which is greater than the density of metals such as steel and copper. This high density requires higher pressure and heat in the manufacturing process, but also makes it have better weight and balance, suitable for occasions that require precise weight control.

2. High hardness: Tungsten ejecting needles have a high hardness, usually 800-1000 HV, which makes tungsten ejecting needles highly wear-resistant and impact-resistant. This hardness also makes it more difficult to process and manufacture during the manufacturing process, but it can produce more durable and sharp tools and components.

3. High thermal conductivity: Tungsten ejecting needles have a high thermal conductivity of 149 W/(m·K), which makes tungsten ejecting needles highly efficient in transferring heat. This high thermal conductivity makes tungsten ejecting needles widely used in the electronics industry to manufacture electronic devices and test probes, as well as in the aerospace field to manufacture high-temperature components and high-temperature components such as combustion chambers of rocket engines.

4. High melting point: Tungsten ejecting needles have a very high melting point of 3410℃, which makes tungsten ejecting needles have good stability in high temperature environments. This high melting point makes tungsten ejecting needles have good application prospects in the manufacture of high-temperature components and materials. For example, in the manufacture of aircraft engines, tungsten ejecting needles are used to manufacture high-temperature components such as combustion chambers due to their good high-temperature performance.

5. Good electrical properties: Tungsten ejecting needles have good electrical properties, and their resistivity and conductivity are high. This good electrical property makes tungsten ejecting needles have good application prospects in the manufacture of electronic devices and test probes.

6. Corrosion resistance: Tungsten ejecting needles have good corrosion resistance in most chemical media, which makes them have good application prospects in the chemical industry and marine environments.

7. Good processing performance: Although the hardness of tungsten ejecting needles is very high, they have good processing performance. By adopting advanced processing technology and tools, tungsten needle products with high precision and good surface quality can be manufactured.

Tungsten ejecting needles have a series of unique performance characteristics such as high density, high hardness, high thermal conductivity, high melting point, good electrical properties, corrosion resistance and good processing performance. These characteristics make tungsten ejecting needles widely used in many fields, such as electronics, automobile manufacturing, aerospace, chemical industry, etc.

More details of tungsten probes, please visit website: http://tungsten.com.cn/tungsten-needles-and-pins.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595